26

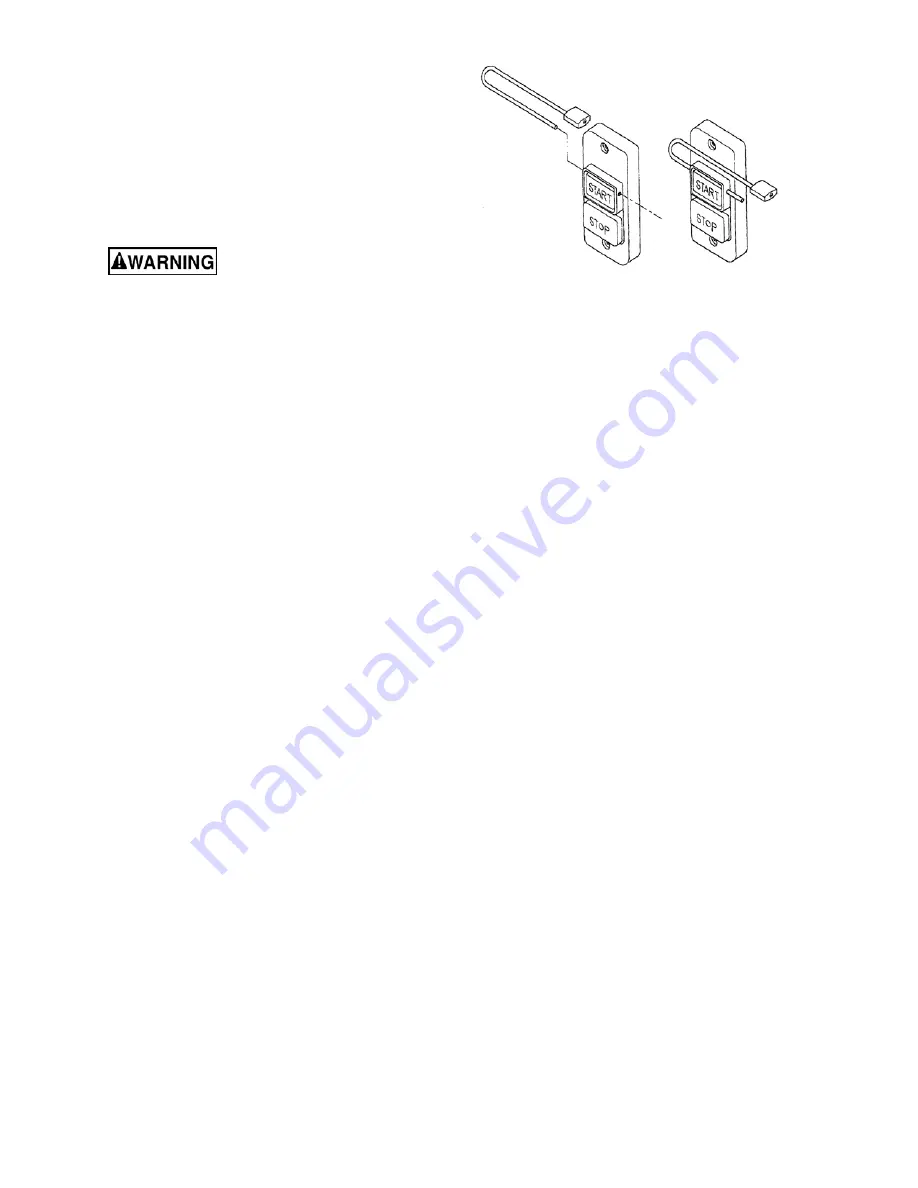

On/Off Switch

The band saw is equipped with a push-button

switch that will accept a safety padlock (not

included). To safeguard your machine from

unauthorized operation and accidental starting

by young children, the use of a padlock is highly

recommended – see Figure 54.

Maintenance

Before doing maintenance,

disconnect machine from electrical supply

by pulling out the plug or switching off the

main switch! Failure to comply may cause

serious injury.

Clean the band saw regularly to remove any

resinous deposits and sawdust. Use a brush,

vacuum or compressed air to blow out excess

dust. (Wear safety goggles while doing this.)

Keep the miter slot in the table free of dust and

debris. Keep the guide bearings clean and free

of resin. Use a commercially available gum and

pitch remover if needed.

Keep the guide post clean; occasionally apply a

light coat of oil.

Oil any pins, shafts, and joints. Do not get oil on

pulleys or belts.

Bearings on the band saw are sealed for life and

do not require attention.

Check that the cleaning brush over the lower

wheel is working properly; adjust if necessary.

Remove any deposits from the band wheels and

tires to avoid vibration and blade breakage.

NOTE: Do not use solvents around tires.

If signs

of wear or deformation occur, replace the tires.

The table surface must be kept clean and free of

rust for best results. If rust appears, use a

mixture of household ammonia, a good

commercial detergent and #000 steel wool.

Alternatively, commercial rust removers can be

found at many hardware stores.

Apply a light, protective coating over the table,

such as paste wax. Products in aerosol form are

also available in hardware stores and supply

catalogs. Whatever method is chosen, the

coating should protect the metal and provide a

smooth surface, without staining the wood.

Figure 54

Summary of Contents for 1791216K

Page 39: ...39 Body Assembly...

Page 41: ...41 Closed Stand Assembly...

Page 43: ...43 Fence and Rail Assembly...