17

9.4

Extension cords

Use of extension cords is discouraged; try to

position machines within reach of the power source.

If an extension cord becomes necessary, be sure to

use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. Table 1 shows correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Ampere

Rating

Volts

Total length of

cord in feet

More

Than

Not

More

Than

120

240

25

50

50

100

100

200

150

300

AWG

0

0

0

6 18

16 16

14

0

6 10 18

16 14

12

10 12 16

16 14

12

12 16 14

12

Not

Recommended

Extension Cord Recommendations

Table 1

10.0

Adjustments

10.1

Table tilt

Refer to Figures 19 and 20.

1. Loosen lock lever (A).

2. For

right tilt

(as viewed from front or operator’s

side of saw), rotate handwheel (B) counter-

clockwise to tilt table up to 45°.

3. For

left tilt

(as viewed from front or operator’s

side of saw), loosen lock lever (A) and rotate

handwheel clockwise a turn or two to release

pressure on the 90° stop bolt (C). Rotate

circular plate (D) out of the way. Then rotate

handwheel clockwise to tilt table up to to 15°.

The now-exposed hole in the band saw body

allows the stop bolt to descend through it, to

keep intact the setting of the 90° stop.

4. Tighten lock lever (A, Figure 20) to secure

setting.

NOTE: The circular plate (D) can be tightened or

loosened as desired by using a 4mm hex wrench on

the screw.

Also, the lever (A, Figure 20) can be pivoted to a

more convenient position. Simply lift straight out on

the lever and rotate it on the pin, then release the

lever making sure it seats itself on the pin.

Figure 19: table tilt

Figure 20: table stop

10.2

90° table stop

Refer to Figures 19 through 21.

The 90° positive stop ensures that table will always

be perpendicular to blade after table is returned to

horizontal position. Check and adjust this 90° stop

as follows:

1. Disconnect machine from power source.

2. Make sure blade is under full tension.

3. Loosen lever (A, Figure 19) and tilt table with

handwheel (B), until stop bolt (C) rests on

circular plate (D).

4. Make sure table insert lies flush with table

surface. Place a square on table and against

blade to check that table is 90° to blade. See

Figure 21.

NOTE: Do not push square into

blade.

5. If table and blade are not square, use a 17mm

wrench to loosen lock nut (E) then rotate stop

bolt. Turn stop bolt as needed until there is no

longer light showing between square and blade.

6. Tighten lock nut (E) to secure table stop

position.

7. Tighten

lever

(A).

8. Check that scale pointer (F, Figure 19) is at

zero. If necessary, loosen screw on pointer and

shift pointer to zero. Then retighten screw.

Summary of Contents for 1791257B

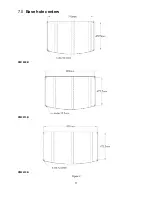

Page 11: ...11 7 0 Base hole centers PM1800B PM2013B PM2415B Figure 2...

Page 35: ...35 17 1 1 Complete Machine with Accessories PM 1800B 2013B Exploded View I...

Page 36: ...36 17 1 2 Complete Machine with Accessories PM 1800B 2013B Exploded View II...

Page 37: ...37 17 1 3 Complete Machine with Accessories PM2415B Exploded View I...

Page 38: ...38 17 1 4 Complete Machine with Accessories PM2415B Exploded View II...

Page 58: ...58 This page intentionally left blank...

Page 59: ...59 This page intentionally left blank...

Page 60: ...60 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com...