22

Remove fence plate and mount resaw pin to the slot

in the fence body, securing it with the knob, as

shown.

The resaw pin is usually positioned so that its center

is approximately even with front edge of blade.

See under “Operation” for further information on

using the resaw pin.

10.12

Miter gauge

Refer to Figures 34 and 35.

A miter gauge is provided for crosscutting

operations. Install miter gauge by sliding the end of

miter gauge bar into table’s T-slot.

The miter gauge should fit snugly within miter slot

while still sliding easily. The bar of the miter gauge

has two slots, each with a set screw (Figure 34).

Rotate one or both of these set screws with a 4mm

hex wrench as needed to eliminate any play

between miter gauge bar and miter slot.

If table/miter slot is square to blade

(sect. 8.10)

, the

miter gauge will also be square to blade. Before

operating, however, the 90° setting of miter gauge

should be checked in relation to the blade, as

follows.

1. Place a square against miter gauge face, and

against flat of blade, as shown in Figure 33.

(Place square against flat of blade, not the teeth

which are set wider than the blade body). A

wide blade is preferred for this procedure.

2. Flip 90° stop plate (C) out of the way, and

loosen handle (A). Shift miter gauge body until

it is flush with square, then retighten handle (A).

3. Flip stop plate (C) back down, and loosen 90°

stop hex nut and adjust screw until it contacts

the 90° stop plate.

4. Retighten hex nut.

5. Loosen set screw at base of pointer (B), and

shift pointer so that it lines up with 90° mark on

scale.

6. Retighten set screw.

The 45° stops can be checked in similar fashion,

using an angle gauge similar to that shown in Figure

37.

To adjust miter gauge angle for operations:

1. Loosen handle (A).

2. Rotate gauge body until pointer (B) lines up with

desired angle on scale. You may have to pivot

90° stop plate (C) out of the way to allow the

body to rotate.

3. Tighten handle (A).

4. There are three stops – at 90°, and 45° left and

right. Each of these can be adjusted by

loosening hex nut (D) and turning screw (E) as

needed. Retighten hex nut (D) when adjustment

is finished.

Figure 34: miter gauge adjustment

Figure 35: miter gauge adjustment

10.13

Blade speed adjustment

Refer to Figures 36 through 38.

Figure 37 shows appropriate belt position to achieve

each speed according to the particular band saw

model.

To change speed:

1. Disconnect machine from power source.

2. Loosen motor lock handle and raise motor lift

handle to release tension on belt.

3. Tighten motor lock handle to keep motor in

raised position.

4. Slide belt onto appropriate set of pulleys.

5. Loosen motor lock handle and allow motor to

lower. The weight of the motor itself should

produce proper tension for the belt. Check

tension by pushing with moderate pressure

against center of belt (Figure 38). An

adequately tensioned belt will deflect about

1/2”. If tension isn’t strong enough, push down

on the motor.

6. Tighten motor lock handle.

Summary of Contents for 1791257B

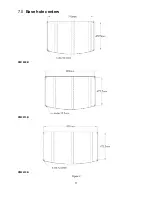

Page 11: ...11 7 0 Base hole centers PM1800B PM2013B PM2415B Figure 2...

Page 35: ...35 17 1 1 Complete Machine with Accessories PM 1800B 2013B Exploded View I...

Page 36: ...36 17 1 2 Complete Machine with Accessories PM 1800B 2013B Exploded View II...

Page 37: ...37 17 1 3 Complete Machine with Accessories PM2415B Exploded View I...

Page 38: ...38 17 1 4 Complete Machine with Accessories PM2415B Exploded View II...

Page 58: ...58 This page intentionally left blank...

Page 59: ...59 This page intentionally left blank...

Page 60: ...60 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com...