23

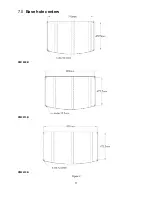

Figure 36: belt detension

Figure 37: belt position

Figure 38: belt deflection

10.14

Drive belt tension and

replacement

The drive belt and pulleys are properly adjusted at

the factory. However, belt tension should be

occasionally checked when the band saw is new, as

a new belt may stretch slightly during the breaking-

in process.

If the belt becomes worn, cracked, frayed or glazed,

it should be replaced as follows:

Refer to Figures 36 and 38.

1. Disconnect machine from power source.

2. Open upper and lower doors and remove blade.

3. Remove screw from lower wheel shaft and

remove lower wheel.

4. Loosen motor lock handle.

5. Raise motor lift handle and retighten motor lock

handle to hold motor in raised position.

6. Remove old belt and install new one, making

sure it seats properly in the pulley grooves.

7. Loosen motor lock handle and allow motor to

lower.

8. The weight of the motor itself should generally

produce the proper tension for the belt. Check

tension by pushing with moderate pressure

against center of belt (Figure 38). An

adequately tensioned belt will deflect about

1/2”. If tension isn’t strong enough, push down

on the motor.

9. Tighten motor lock handle, reinstall lower

wheel, and install hex nut securely on shaft.

10. Re-check blade tension and tracking before

operating saw.

Summary of Contents for 1791257B

Page 11: ...11 7 0 Base hole centers PM1800B PM2013B PM2415B Figure 2...

Page 35: ...35 17 1 1 Complete Machine with Accessories PM 1800B 2013B Exploded View I...

Page 36: ...36 17 1 2 Complete Machine with Accessories PM 1800B 2013B Exploded View II...

Page 37: ...37 17 1 3 Complete Machine with Accessories PM2415B Exploded View I...

Page 38: ...38 17 1 4 Complete Machine with Accessories PM2415B Exploded View II...

Page 58: ...58 This page intentionally left blank...

Page 59: ...59 This page intentionally left blank...

Page 60: ...60 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com...