25

12.0

Operation

The following section contains basic information,

and is not intended to cover all possible applications

or techniques using the Band Saw. Consult

published sources of information, acquire formal

training, and/or talk to experienced Band Saw users

to gain proficiency and knowledge of band saw

operations.

The following Figures may or may not show your

particular model, but the procedures are the same.

12.1

General procedure

1. Make sure the blade is adjusted correctly for

tension and tracking, and that upper and lower

guide bearings and thrust bearings are set in

proper relation to the blade.

2. Adjust guide post so that the guide bearings are

just above the workpiece (about 3/16”) allowing

minimum exposure to the blade.

3. If using the fence, move it into position and lock

it to the guide rail. If you are using the miter

gauge for a crosscut, the fence should be

moved safely out of the way.

4. Turn on the band saw and allow a few seconds

for the machine to reach full speed.

Whenever possible, use a push

stick, hold-down, power feeder, jig, or similar

device while feeding stock, to prevent your

hands getting too close to the blade.

5. Place the straightest edge of the workpiece

against the fence for a rip cut; or against the

miter gauge for a crosscut.

6. Push the workpiece slowly into the blade, while

also keeping it pressed against the fence or

held against the miter gauge. Do not force the

workpiece into the blade.

Some further operating tips:

Make

relief cuts

whenever possible. A relief cut is an

extra cut made through the waste portion of a

workpiece up to the layout line. When that

intersection is reached by the blade while following

the layout line, the waste portion comes free. This

helps prevent pinching of the back edge of the blade

in the cut.

When cutting, do not overfeed

the blade; overfeeding will reduce blade life, and

may cause the blade to break.

When cutting long stock, the operator should use

roller stands, support tables, or an assistant to help

stabilize the workpiece.

12.2

Ripping

Ripping is cutting lengthwise down the workpiece,

and with the grain (of wood stock). See Figure 41.

Always use a push stick or similar device when

ripping narrow pieces.

Figure 41: ripping

12.3

Crosscutting

Crosscutting is cutting across the grain of the

workpiece, while using the miter gauge to feed the

workpiece into the blade.

The right hand should hold the workpiece steady

against the miter gauge, while the left hand pushes

the miter gauge past the blade, as shown in Figure

42.

Do not use the fence in conjunction with the miter

gauge. The offcut of the workpiece must not be

constrained during or after the cutting process.

Using the fence in conjunction

with the miter gauge can cause binding and

possible damage to the blade.

Figure 42: crosscutting

Summary of Contents for 1791257B

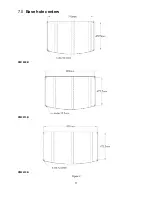

Page 11: ...11 7 0 Base hole centers PM1800B PM2013B PM2415B Figure 2...

Page 35: ...35 17 1 1 Complete Machine with Accessories PM 1800B 2013B Exploded View I...

Page 36: ...36 17 1 2 Complete Machine with Accessories PM 1800B 2013B Exploded View II...

Page 37: ...37 17 1 3 Complete Machine with Accessories PM2415B Exploded View I...

Page 38: ...38 17 1 4 Complete Machine with Accessories PM2415B Exploded View II...

Page 58: ...58 This page intentionally left blank...

Page 59: ...59 This page intentionally left blank...

Page 60: ...60 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com...