5

3.0

IMPORTANT SAFETY

INSTRUCTIONS

WARNING: For your own safety read instruction

manual before operating Band Saw.

- Wear eye protection.

- Do not remove jammed cutoff pieces until blade

has stopped.

- Maintain proper adjustment of blade tension, blade

guides, and thrust bearings.

- Adjust upper guide to just clear workpiece.

- Hold workpiece firmly against table.

1. Read and understand entire owner's manual

before attempting assembly or operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace warning labels if they become

obscured or removed.

4. This band saw is designed and intended for use

by properly trained and experienced personnel

only. If you are not familiar with the proper and

safe operation of a band saw, do not use until

proper training and knowledge have been

obtained.

5. Do not use this band saw for other than its

intended use. If used for other purposes,

Powermatic disclaims any real or implied

warranty and holds itself harmless from any

injury that may result from that use.

6. Always wear approved safety glasses/face

shield while using this machine. (Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.)

7. Before operating band saw, remove tie, rings,

watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and

confine long hair. Non-slip footwear or anti-skid

floor strips are recommended. Do not wear

gloves.

8. Keep work area clean. Cluttered areas and

benches invite accidents.

9. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Table 1 shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gage. The smaller the gage number, the

heavier the cord.

10. Secure work. Use clamps or a vise to hold work

when practical. It’s safer than using your hand

and it frees both hands to operate tool.

11.

Disconnect tools before servicing; when

changing accessories, such as blade, bits,

cutters and the like.

12. Direction of feed: Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

13. Adjust upper blade guides to approximately 1/8”

above workpiece.

14. Make sure blade tension, tracking and blade

guides are all properly adjusted.

15. Make relief cuts where possible, when cutting

curved stock.

16. When feeding small work pieces into blade,

always use push stick, fixture, or similar device

to keep hands at a safe distance.

17. Hold stock firmly and flat against table.

18. Wear ear protectors (plugs or muffs) during

extended periods of operation.

19.

WARNING: Drilling, sawing, sanding or

machining wood products generates wood dust

and other substances known to the State of

California to cause cancer. Avoid inhaling dust

generated from wood products or use a dust

mask or other safeguards to avoid inhaling dust

generated from wood products.

20. Wood products emit chemicals known to the

State of California to cause birth defects or

other reproductive harm. (California Health and

Safety Code Section 25249.6)

21. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

22. Make certain switch is in OFF position before

connecting machine to power supply.

23. Make certain machine is properly grounded.

24. Do not back stock out of blade while blade is

running.

25. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

Summary of Contents for 1791257B

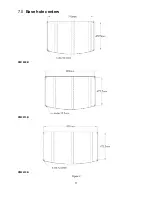

Page 11: ...11 7 0 Base hole centers PM1800B PM2013B PM2415B Figure 2...

Page 35: ...35 17 1 1 Complete Machine with Accessories PM 1800B 2013B Exploded View I...

Page 36: ...36 17 1 2 Complete Machine with Accessories PM 1800B 2013B Exploded View II...

Page 37: ...37 17 1 3 Complete Machine with Accessories PM2415B Exploded View I...

Page 38: ...38 17 1 4 Complete Machine with Accessories PM2415B Exploded View II...

Page 58: ...58 This page intentionally left blank...

Page 59: ...59 This page intentionally left blank...

Page 60: ...60 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com...