2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service

Centers located throughout the United States can give you quick service. In most cases, any of these WMH Tool Group

Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and

major repair on your POWERMATIC

®

tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with your

local WMH Tool Group distributor, or visit powermatic.com.

WARRANTY

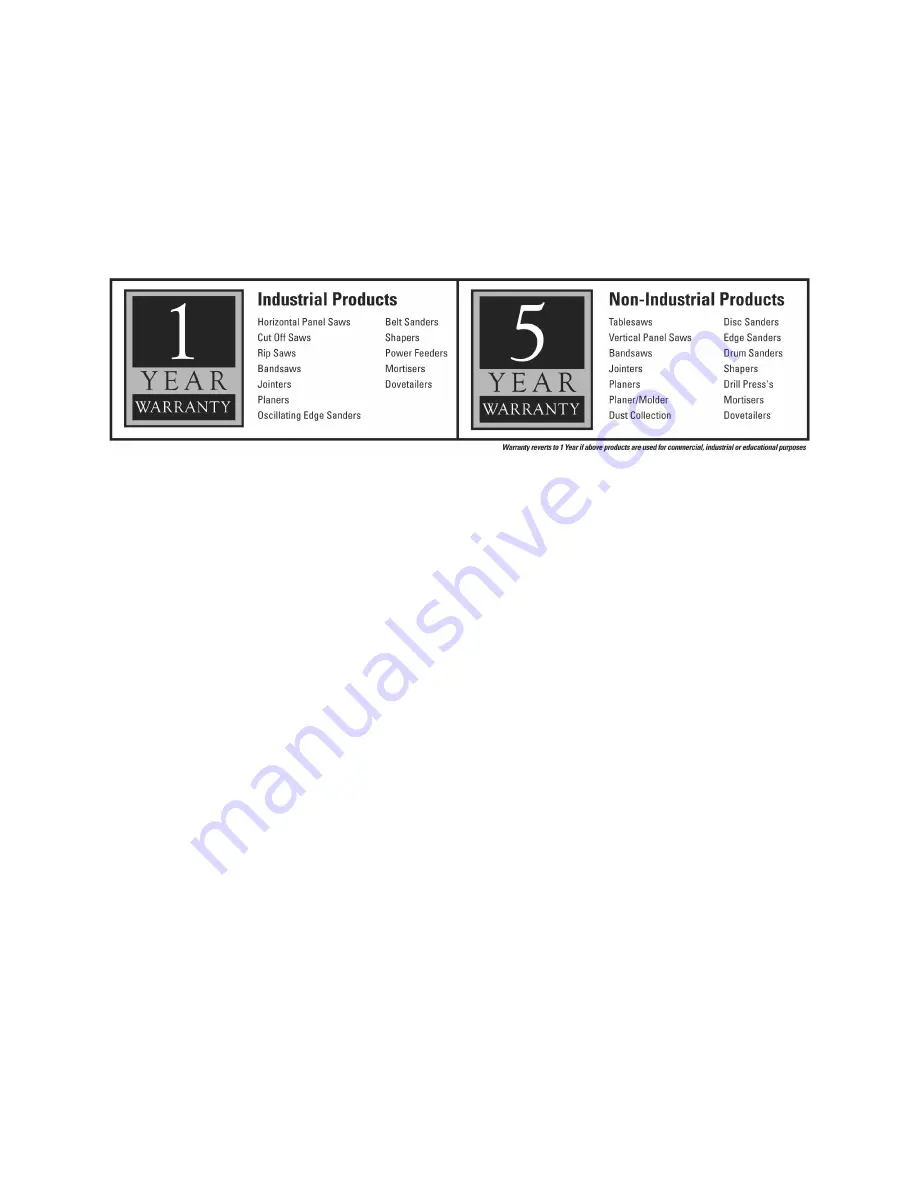

POWERMATIC products carry a limited warranty which varies in duration based upon the product.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

The Five Year Warranty does not cover products used for commercial, industrial or educational purposes. Products with a Five

Year Warranty that are used for commercial, industrial or education purposes revert to a One Year Warranty. This warranty does

not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair or

alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose to have the product returned, you will be responsible for the handling and shipping costs of the

return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information and are

not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

Summary of Contents for 1791291K

Page 7: ...7 Dimensions Figure 1 ...

Page 19: ...19 Guide to Sanding Belts and Discs ...

Page 23: ...23 31A Sander Body Assembly ...

Page 25: ...25 31A Stand Assembly 1PH ...

Page 27: ...27 31A Stand Assembly 3PH ...

Page 28: ...28 Electrical Connections 1 Phase ...

Page 29: ...29 Electrical Connections 3 Phase ...

Page 30: ...30 NOTES ...

Page 31: ...31 ...