19

NOTE: One notch of the scale equals 1mm.

6. With your fingers on the shank portion of the

cutter, carefully rotate the cutter toward the

plus (+) or minus (-) position as needed.

7. When satisfied with the adjustment, tighten

both set screws firmly.

8. Re-attach the spring on the headstock, and

re-install the dust hood.

Drive Belt Tension

The tightness of the belt that drives the spindle

has been adjusted at the factory. Further

adjustment may be necessary after the machine

receives some use, as the belt may stretch

slightly during the “breaking in” process.

Belt tension can be adjusted by a socket head

cap screw at the rear of the headstock (Figure

26) which slides the motor toward or away from

the spindle. To tighten the belt, rotate this cap

screw clockwise with a 6mm hex wrench. To

loosen the belt, rotate the cap screw

counterclockwise. The belt should be just tight

enough to prevent it slipping on the spindle

during operation.

Replacing cutter

The cutter is very sharp; use

caution when working with or around cutter.

Disconnect machine from power source!

Failure to comply may cause serious injury.

1. To replace the cutter, loosen both set

screws (Figure 25) and carefully pull up on

the cutter until it is free from the spindle.

2. Slide the new cutter down into the spindle,

and align the cutting edge with your

previous setting on the spindle scale.

3. Tighten both set screws.

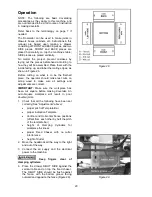

Oil Output

Oil is distributed through the air lines for

constant lubrication of the clamping system. The

oil output can be adjusted by rotating the oil

regulator knob (A, Figure 27). Turn the knob

counterclockwise to increase oil output,

clockwise to decrease oil output.

The level of oil should be checked occasionally

and re-filled as necessary. A minimum level is

marked on the window of the oil cup (C, Figure

27). Refill by removing the screw (B, Figure 27)

and pouring oil into the fill hole. When finished,

re-install screw (B, Figure 27). Use standard air

tool oil. This is available from your local

distributor, or can be found in most hardware

and tool stores.

Figure 26

Figure 27

Summary of Contents for 1791305

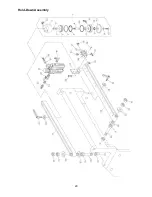

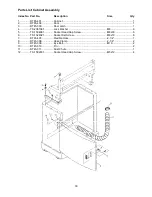

Page 27: ...27 Base Assembly ...

Page 29: ...29 Hold Down Assembly ...

Page 32: ...32 Headstock Assembly ...

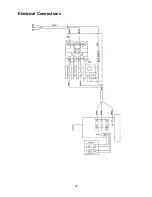

Page 34: ...34 Electrical Connections ...

Page 35: ...35 ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com ...