21

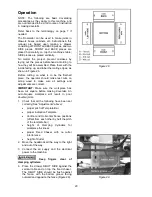

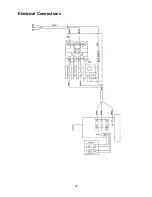

5. Activate the clamping cylinder in front of the

RIGHT SIDE workpiece.

6. Place the drawer BACK on the horizontal

table, and against the horizontal fence. Slide

it flush against the RIGHT SIDE workpiece.

The bottom groove on the BACK should

face downward and opposite the fence. See

Figure 30.

7. Activate the clamping cylinder above the

BACK workpiece.

8. The BACK is now butting against the RIGHT

SIDE so they are flush, with the RIGHT

SIDE overlapping the edge of the BACK.

Both workpieces should be firmly and

evenly against the fences.

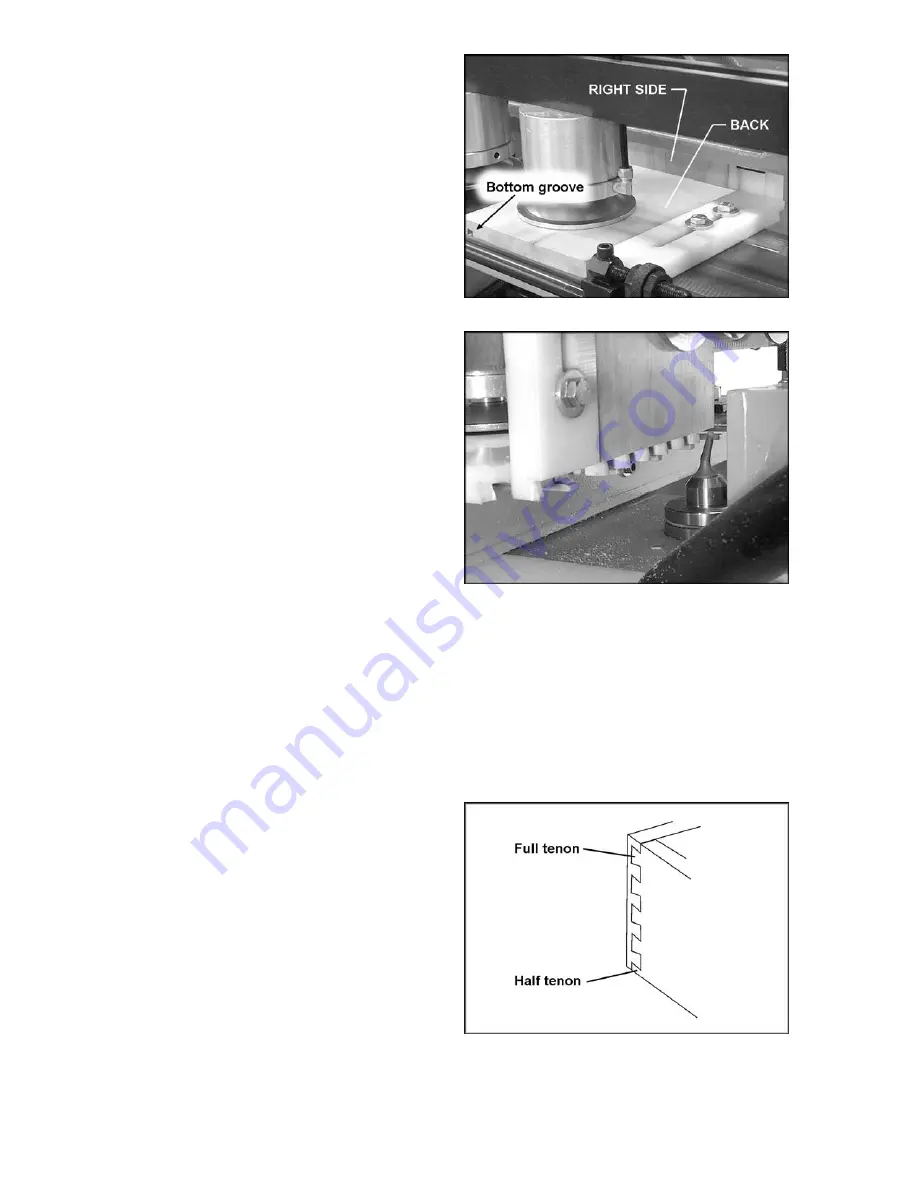

9. Turn on the machine at the switch, and slide

the headstock to the left edge of the

workpiece. Move the cutter in sequence, left

to right, allowing the tracer pin to move in

and out of the template slots. See Figure 31.

You can watch the progress of the cutter

through the window of the dust hood.

NOTE:

Do not rush the cut; allow the cutting

unit to do the work.

10. When finished, slide the headstock out of

the way and unclamp the workpieces by

turning the clamping cylinder levers to “off”.

11. Fit the BACK and RIGHT SIDE together and

examine the joint. If the joint is not

satisfactory, make any needed corrections

to your settings as explained under

“Adjustments.” If the joint is satisfactory,

proceed with the next cut as follows.

12. Insert the LEFT SIDE piece and clamp it in

vertical position and against the fence.

(NOTE: The bottom groove on the LEFT

SIDE will face outward and toward the

fence.)

13. Turn the BACK 180 degrees and clamp it in

the horizontal position against the fence.

(NOTE: The bottom groove on the BACK

workpiece will still be face down, but toward

the fence.)

14. Make the cut, then continue the dovetailing

procedure with the FRONT piece, making

cuts “C” and “D” (Figure 28) until all four

joints of the drawer have been cut.

TIP:

When using drawer side widths that are not

“whole inch” sizes, you may wish to gauge off

the top of the drawer rather than the bottom

when placing workpieces in the machine. Doing

this will improve the look of the drawer by

providing a full tenon near the top of the drawer

and the half-tenon will end up at the bottom. See

Figure 32.

Figure 30

Figure 31

Figure 32

Summary of Contents for 1791305

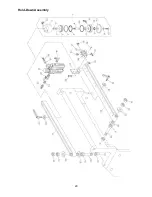

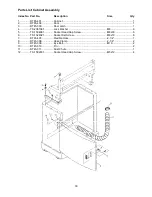

Page 27: ...27 Base Assembly ...

Page 29: ...29 Hold Down Assembly ...

Page 32: ...32 Headstock Assembly ...

Page 34: ...34 Electrical Connections ...

Page 35: ...35 ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com ...