18

Riving Knife Adjustment

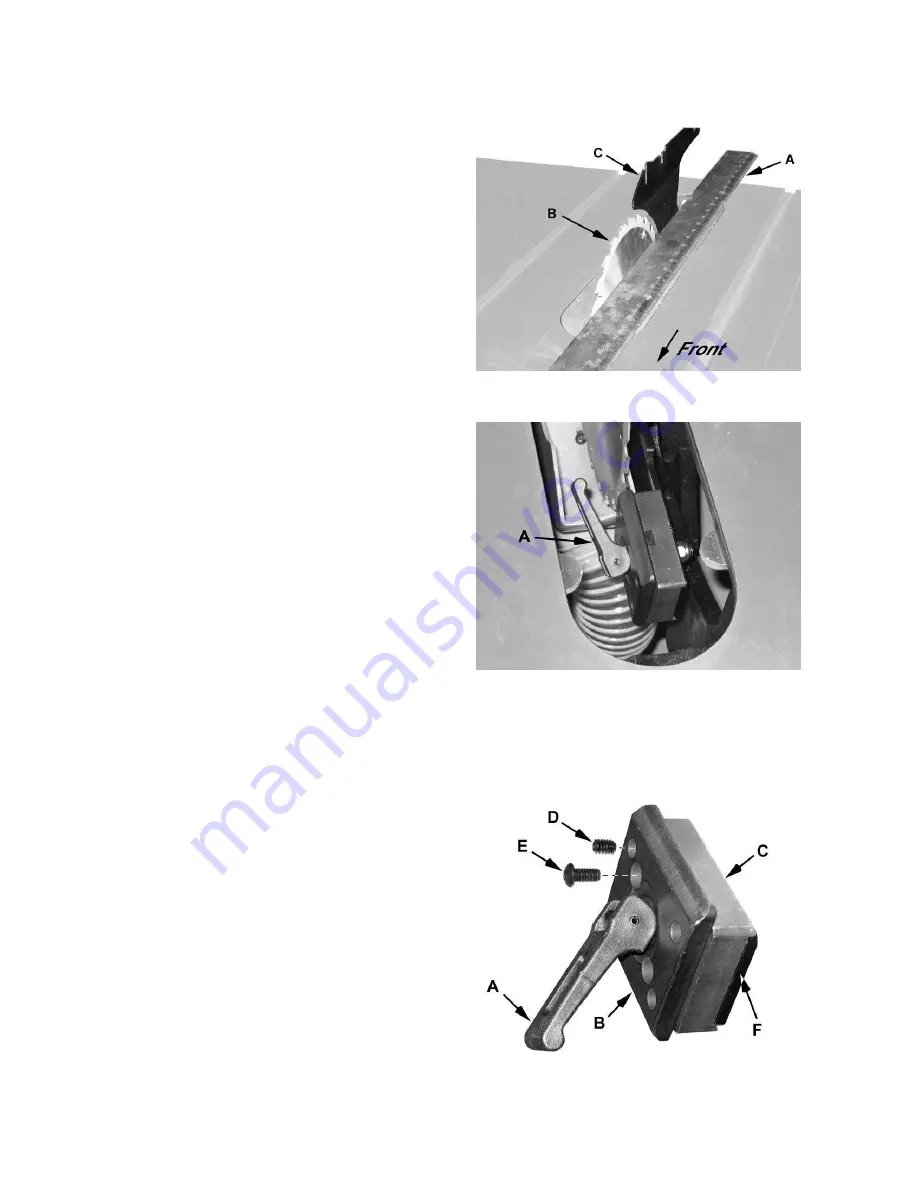

Lateral alignment

The saw blade and riving knife must be in line as

close as possible with each other (

lateral

alignment)

for the prevention of kickback. Upon

initial blade guard and riving knife installation no

further adjustment should be necessary. Alignment

should be checked and adjusted, if required, after

each blade change.

Check the alignment as follows:

1. Remove the

blade guard

and

pawl

(C, E,

Fig. 9).

2. Place

a

straightedge

(A, Fig. 17) on the table

so it rests against the

blade

(B, Fig 17) and

riving knife

(C, Fig. 17). Rotate the blade so the

top of the blade tooth touches the straightedge.

The saw blade and riving knife must be in line.

If adjustment is required:

3. Remove

the

blade guard

(C, Fig. 9) and

table

insert

.

4. Loosen the

lock handle

(A, Fig. 18) and

remove the riving knife, making a note as to

which direction the riving knife needs to be

moved to align it with the saw blade.

5. Using a 3mm hex wrench, make adjustments

to four

set screws

(D, Fig. 19) accessible

through openings located in the corners of the

floating clamp block

(B, Fig. 19).

Adjust any number of setscrews required to

bring the riving knife in alignment with the saw

blade. Then reinsert the riving knife, secure by

tightening the

lock handle

(A, Fig. 18) and

check the alignment per step 2.

Note:

Position the lock handle

towards

the saw

blade as shown in Figure 18. This will avoid the

table insert from being lifted when the blade is

raised with the handwheel.

6. Repeat steps 3–5 until the alignment is correct.

Blade proximity alignment

The gap between the saw blade and riving knife

must be between 3 and 8mm (Figure 20). If

adjustment is needed, note whether the blade to

knife gap needs to be increased or decreased.

Then adjust as follows:

1. Remove the blade guard, pawl, table insert and

riving knife.

Referring to Figure 19:

2. With a 5mm hex wrench, loosen two

socket

head button screws

(E).

Figure 17

Figure 18

Figure 19

Summary of Contents for 1792000K

Page 31: ...31 Table Cabinet Assembly ...

Page 35: ...35 Trunnion Motor Assembly ...

Page 37: ...37 Blade Guard Miter Gauge Assembly ...

Page 42: ...42 Notes ...

Page 43: ...43 ...