12

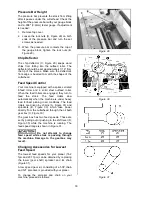

When planing smooth stock the rollers should be

set at low position.

NOTE: When raising the roller higher above the

table, the range is from .003" to .006" (Figure

14).

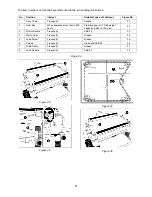

The table rollers are factory set for average

planing and are parallel to the table surface. If

you desire to adjust the table rollers higher or

lower, proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge across both rollers.

3. On one side of the table, loosen the set

screws (Figure 15) with a 3mm hex wrench,

and turn the eccentric shafts to raise or

lower the rollers.

4. When proper height is achieved, tighten set

screws.

5. Adjust the rollers from the opposite side of

the table in the same manner.

IMPORTANT

: Be sure that the height of front

and rear rollers are the same. The table rollers

must always be set parallel to the table.

Cutterhead

Although your planer was carefully adjusted at

the factory, it should be checked before being

put into operation. Any inaccuracies due to

rough handling in transit can be corrected by

following the directions in this manual.

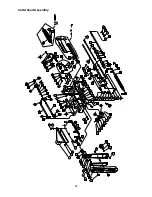

To check the adjustments you will need a knife-

setting gauge (provided), feeler gauges, and a

dial gauge or home-made gauge block made of

hardwood. This gauge block can be made by

following the dimensions shown in Figure 16.

You will also need to remove the belt guard, so

you can rotate the cutterhead using the pulley.

Knife Adjustments (Model 209 only)

When checking or adjusting cutterhead knives

on the model 209 Planer, proceed as follows:

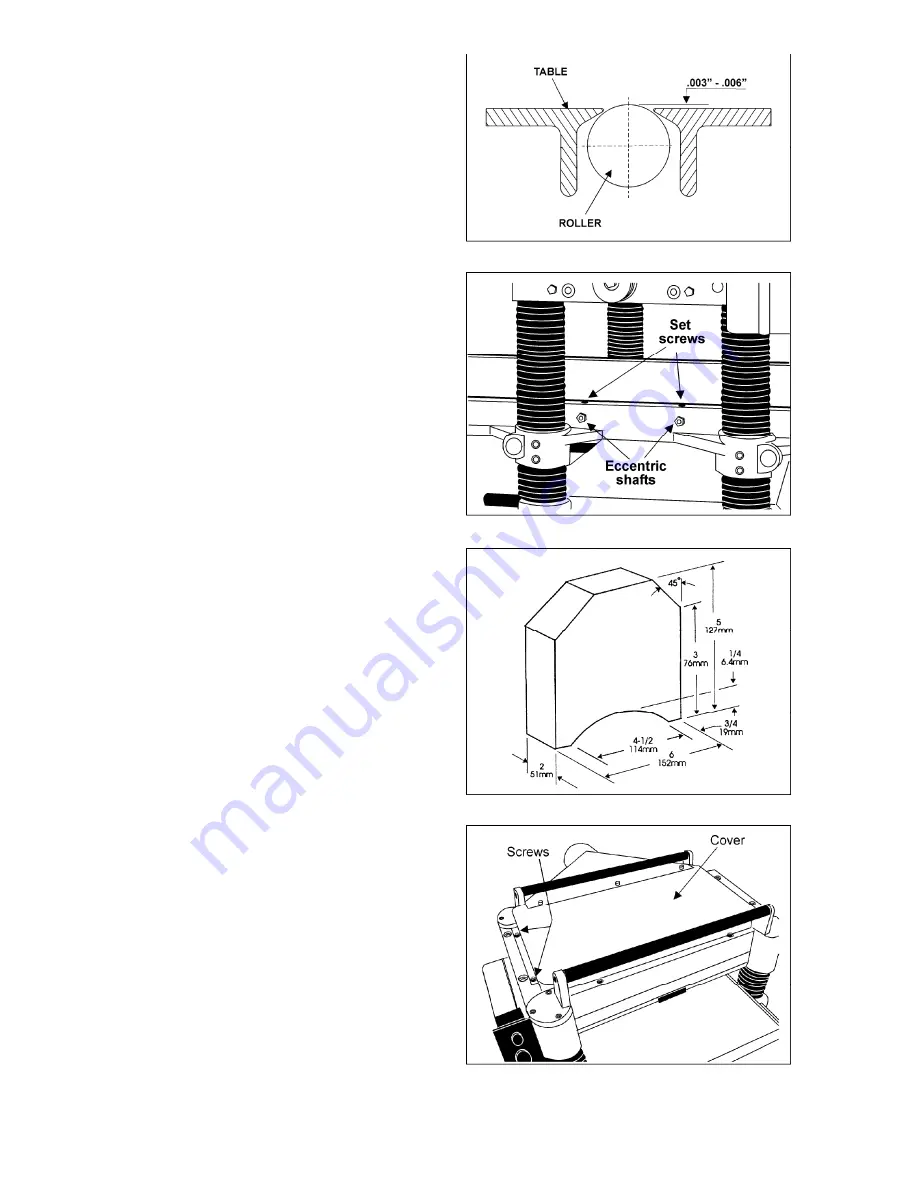

1. Disconnect machine from power source.

2. Remove the six screws and upper cover

(Figure 17).

3. To check and adjust knives, use the

provided knife setting gauge and check all

four knives. Knives should just contact the

bottom of the center protrusion (D, Figure

18) of the knife gauge. Make sure the feet of

the knife gauge sit solidly upon the

cutterhead, and that its shaft is parallel to

the cutterhead (see Figure 19).

Figure 14

Figure 15

Figure 16

Figure 17

Summary of Contents for 209-1

Page 25: ...25 Cutterhead Assembly ...

Page 28: ...28 Base Assembly ...

Page 30: ...30 Gearbox Assembly ...

Page 35: ...35 Electrical Connections Single Phase 230 Volt only ...

Page 39: ...39 ...

Page 40: ...40 427 New Sanford Rd LaVergne TN 37086 Phone 800 274 6848 www powermatic com ...

Page 65: ...25 Dispositif de la tête de la découpeuse ...

Page 68: ...28 Montage de la base ...

Page 70: ...30 Dispositif de la boîte de vitesses ...

Page 75: ...35 Connexions électriques phase unique 230 volts uniquement ...

Page 79: ...39 ...

Page 80: ...40 427 New Sanford Rd LaVergne TN 37086 Téléphone 800 274 6848 www powermatic com ...

Page 105: ...25 Conjunto de Cabeza de Corte ...

Page 108: ...28 Conjunto de Base ...

Page 110: ...30 Conjunto de la Caja de Velocidades ...

Page 115: ...35 Conexiones Eléctricas Monofásico 230 Voltios solamente ...

Page 119: ...39 ...

Page 120: ...40 427 New Sanford Rd LaVergne TN 37086 Teléf 800 274 6848 www powermatic com ...