16

Anti-Kickback Fingers

The anti-kickback fingers (A, Figure 23) are an

important safety feature, as they help prevent

kickback of stock. They operate by gravity and

should be inspected frequently to make sure

they are free of gum and pitch, so that they

move independently and operate correctly.

Infeed and Outfeed Roller Spring

Tension

The infeed roller (B, Figure 23) and outfeed

roller (F, Figure 23) are those parts of your

planer that feed the stock while it is being

planed. The infeed roller and the outfeed roller

are under spring tension and this tension must

be sufficient to feed the stock uniformly through

the planer without slipping but should not be so

tight that it causes damage to the board. The

tension should be equal at both ends of each

roller. Note: Contact Powermatic Technical

Service before attempting any adjustments to

spring tension.

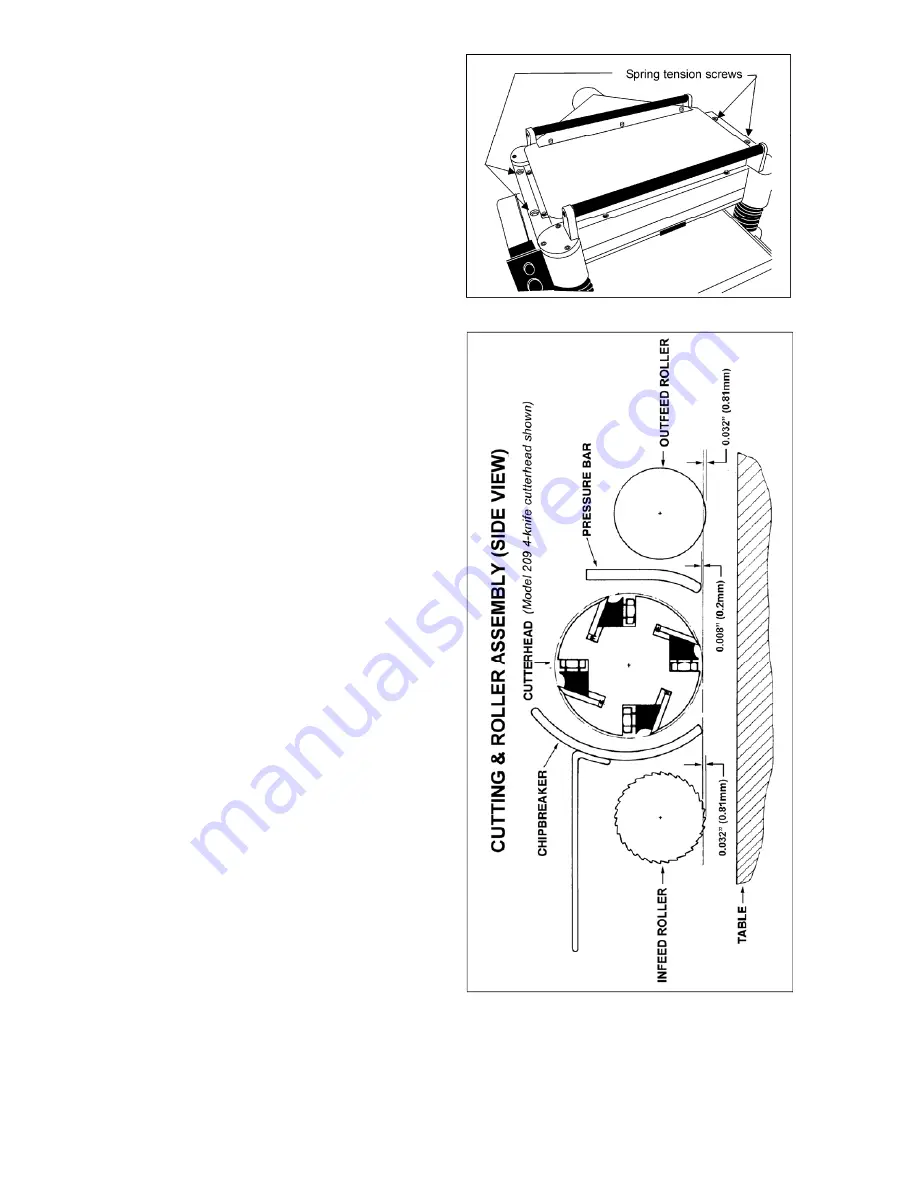

Height of Infeed Roller, Chipbreaker,

Pressure Bar and Outfeed Roller

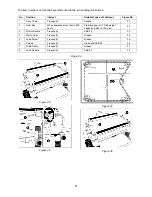

The infeed roller, chipbreaker, pressure bar and

outfeed roller are adjusted at the factory. The

height relationship between these items and the

cutterhead is crucial for accurate and safe

planing. The infeed roller and outfeed roller

should be set 0.032" (0.81mm) below the arc of

the knives. The pressure bar is set 0.006” to

0.008” above the arc of the knives. The

chipbreaker is set even with the knife arc. See

Figure 25.

If any adjustments are necessary for the infeed

roller, chipbreaker, pressure bar or outfeed

roller, they should be done carefully. Use the

following steps as an example of procedure.

NOTE: This procedure uses a home-made

gauge block and feeler gauges, which should be

sufficient for most planer operations. If extra

precise measurements are desired, however,

use a dial indicator device.

Figure 24

Figure 25

Summary of Contents for 209-1

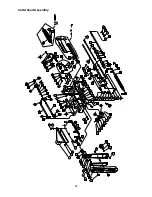

Page 25: ...25 Cutterhead Assembly ...

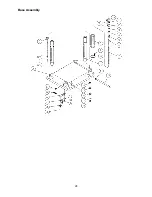

Page 28: ...28 Base Assembly ...

Page 30: ...30 Gearbox Assembly ...

Page 35: ...35 Electrical Connections Single Phase 230 Volt only ...

Page 39: ...39 ...

Page 40: ...40 427 New Sanford Rd LaVergne TN 37086 Phone 800 274 6848 www powermatic com ...

Page 65: ...25 Dispositif de la tête de la découpeuse ...

Page 68: ...28 Montage de la base ...

Page 70: ...30 Dispositif de la boîte de vitesses ...

Page 75: ...35 Connexions électriques phase unique 230 volts uniquement ...

Page 79: ...39 ...

Page 80: ...40 427 New Sanford Rd LaVergne TN 37086 Téléphone 800 274 6848 www powermatic com ...

Page 105: ...25 Conjunto de Cabeza de Corte ...

Page 108: ...28 Conjunto de Base ...

Page 110: ...30 Conjunto de la Caja de Velocidades ...

Page 115: ...35 Conexiones Eléctricas Monofásico 230 Voltios solamente ...

Page 119: ...39 ...

Page 120: ...40 427 New Sanford Rd LaVergne TN 37086 Teléf 800 274 6848 www powermatic com ...