18

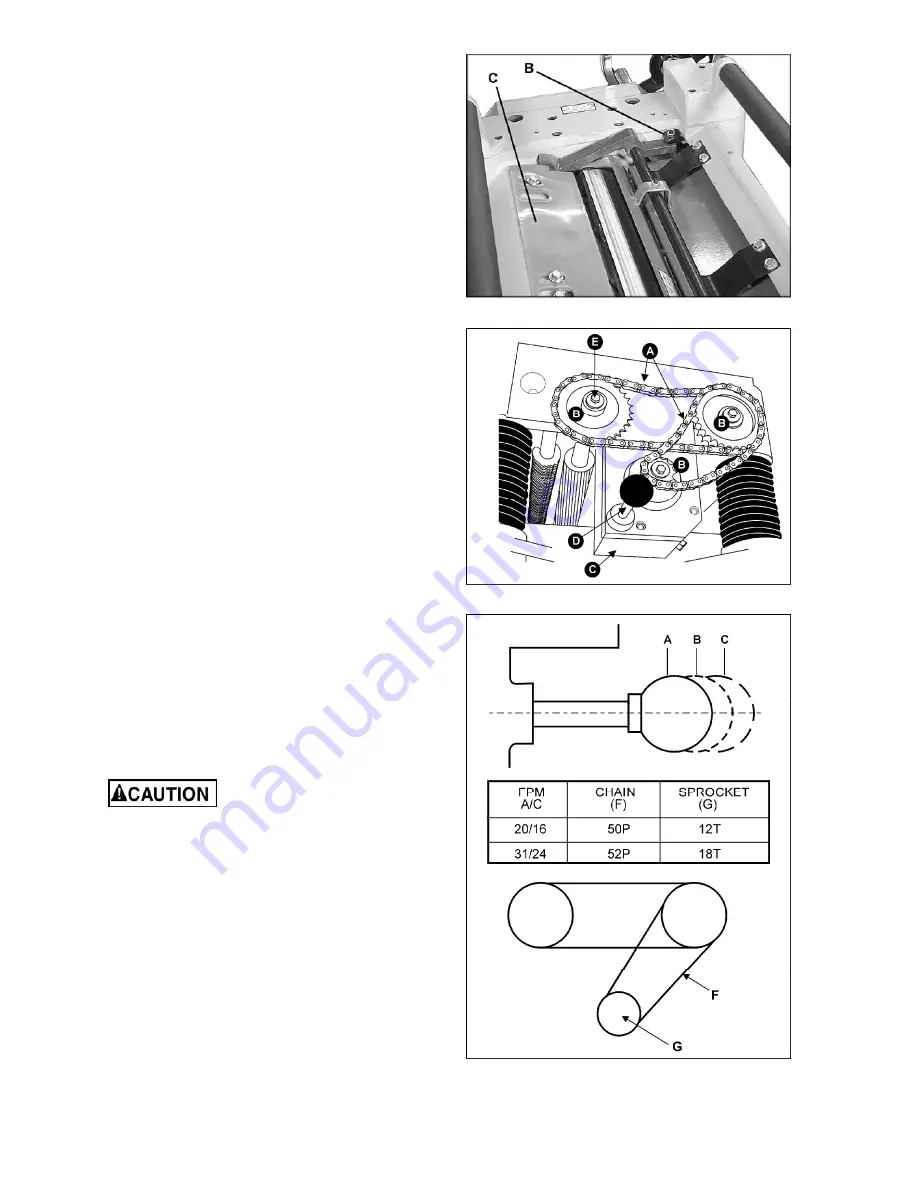

Pressure Bar Height

The pressure bar prevents the stock from lifting

after it passes under the cutterhead. Check the

height of the pressure bar with your gauge block

and a .008" (0.2mm) feeler gauge. If adjustment

is needed:

1. Remove top cover.

2. Loosen the lock nuts (B, Figure 29) on both

ends of the pressure bar and turn the set

screws as needed.

3.

When the pressure bar contacts the top of

the gauge block, tighten the lock nuts (B,

Figure 29).

Chip Deflector

The chip deflector (C, Figure 29) keeps wood

chips from falling into the outfeed roller. The

deflector should be set approximately 1/16" from

the tip of the knives. Make sure the deflector's

front edge is beveled to match the shape of the

cutterhead.

Feed Speed Control

Your machine is equipped with a spiral, serrated

infeed roller and a solid steel outfeed roller.

When the feed rollers are engaged, they turn to

feed the stock. The feed rollers slow

automatically when the machine is under heavy

load for best planing in all conditions. The feed

rollers are driven by chains (A, Figure 30) and

sprockets (B, Figure 30) which take power

directly from the cutterhead through the oil bath

gear box (C, Figure 30).

The gear box has two feed speeds. These are

set by pulling out or pushing in the shift lever (D,

Figure 30) while the machine is running. The

feed speed range is shown in Figure 31.

Do not attempt to change

feed speed while stock is passing through

the machine. Damage to the gearbox may

result.

Changing Accessories for Lowest

Feed Speed

The lowest feed speeds for your planer (16.2

fpm and 20.7 fpm) can be obtained by replacing

the lower (gear shaft) sprocket and its chain

(Figure 31).

A low speed gear kit, consisting of a 50P chain

and 12T sprocket, is provided with your planer.

To change the sprocket and chain on your

machine, proceed as follows:

Figure 29

Figure 30

Figure 31

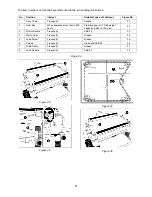

Summary of Contents for 209-1

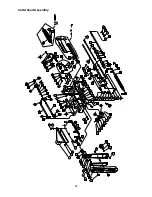

Page 25: ...25 Cutterhead Assembly ...

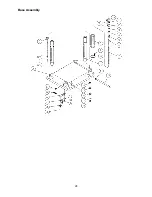

Page 28: ...28 Base Assembly ...

Page 30: ...30 Gearbox Assembly ...

Page 35: ...35 Electrical Connections Single Phase 230 Volt only ...

Page 39: ...39 ...

Page 40: ...40 427 New Sanford Rd LaVergne TN 37086 Phone 800 274 6848 www powermatic com ...

Page 65: ...25 Dispositif de la tête de la découpeuse ...

Page 68: ...28 Montage de la base ...

Page 70: ...30 Dispositif de la boîte de vitesses ...

Page 75: ...35 Connexions électriques phase unique 230 volts uniquement ...

Page 79: ...39 ...

Page 80: ...40 427 New Sanford Rd LaVergne TN 37086 Téléphone 800 274 6848 www powermatic com ...

Page 105: ...25 Conjunto de Cabeza de Corte ...

Page 108: ...28 Conjunto de Base ...

Page 110: ...30 Conjunto de la Caja de Velocidades ...

Page 115: ...35 Conexiones Eléctricas Monofásico 230 Voltios solamente ...

Page 119: ...39 ...

Page 120: ...40 427 New Sanford Rd LaVergne TN 37086 Teléf 800 274 6848 www powermatic com ...