24

Straight Line Bevel Shaping

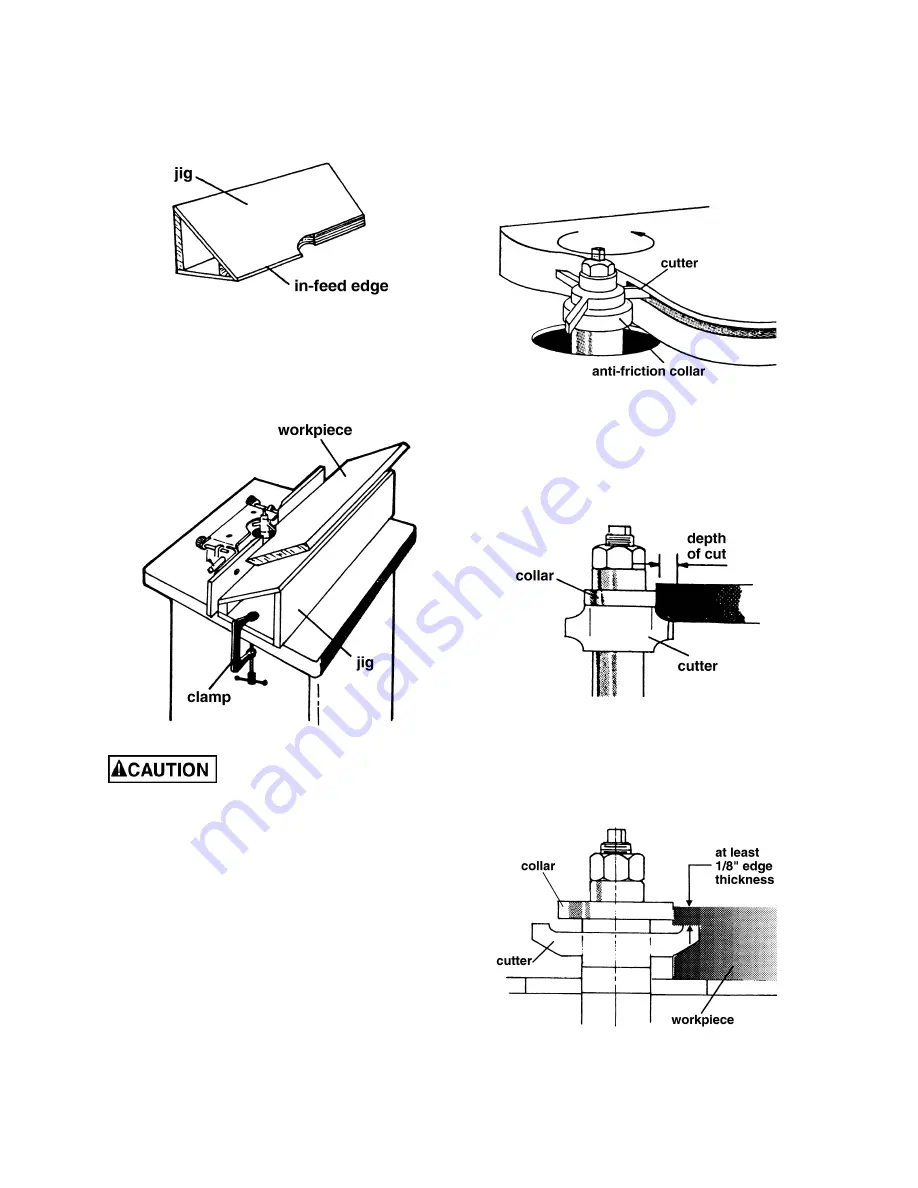

To shape a beveled straight edge, use a bevel-

edge shaping jig in combination with the regular

fence as shown in Figure 34.

Figure 34

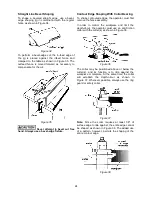

To perform a bevel-edge cut, the in-feed edge of

the jig is placed against the infeed fence and

clamped to the table as shown in Figure 35. The

outfeed fence is moved forward as necessary to

compensate for the cut.

Figure 35

Never attempt to bevel cut free

hand. Always use a bevel-edge fixture.

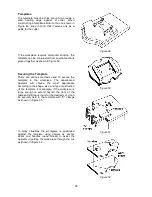

Contour Edge Shaping With Collar Bearing

To shape contoured edges, the operator must first

remove the fence assembly.

In order to control the workpiece and limit the

depth-of-cut, the operator must use an anti-friction

collar with the cutter(s) as shown in Figure 36.

Figure 36

The collar may be positioned above or below the

cutter(s), and its function is to ride against the

workpiece or template. At the same time, the collar

will establish the depth-of-cut as shown in

Figure 37. Whenever possible, always use the ring

guard or safety collar.

Figure 37

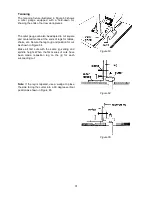

Note:

Since the collar requires at least 1/8" of

surface edge to ride against, the entire edge cannot

be shaped as shown in Figure 38. The added use

of a pattern, however, permits the shaping of the

entire contour edge.

Figure 38

Summary of Contents for 2700

Page 35: ...35 Table Assembly Drawing ...

Page 37: ...37 Fence Assembly Drawing ...

Page 41: ...41 Elevator Assembly Drawing ...

Page 43: ...43 Caster Assembly Drawing ...

Page 45: ...45 Spindle Assembly Drawing 1 1 4 Spindle 3 4 Spindle 1 Spindle 1 2 Spindle 30mm Spindle ...

Page 48: ...48 Cabinet and Base ...