28

Templates

The template must be thick enough to provide a

solid bearing edge against a collar. Whe n

constructing a template similar to the one shown in

Figure 49, keep in mind that it serves only as a

guide for the cutter.

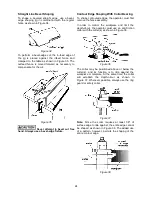

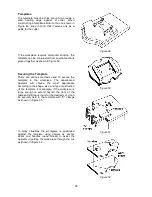

If the workpiece requires all-around shaping, the

template can be constructed from several sections

pieced together as shown in Figure 50.

Securing the Template

There are various methods used to secure the

template to the workpiece. The experienced

operator will choose the most appropriate

according to the shape, size, and type constructio n

of the template. For example, if the workpiece is

large enough to extend beyond the front of the

table and still leave room for the desired cut, it ca n

be securely held to the template with "C" clamps

as shown in Figure 51.

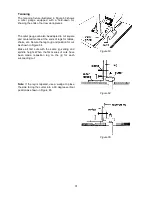

In many situations the workpiece is positioned

against the template using dowels as anchor

points and handles (wood blocks) to assist the

operator in guiding the work-piece through the cut

as shown in Figure 52.

Figure 49

Figure 50

Figure 51

Figure 52

Summary of Contents for 2700

Page 35: ...35 Table Assembly Drawing ...

Page 37: ...37 Fence Assembly Drawing ...

Page 41: ...41 Elevator Assembly Drawing ...

Page 43: ...43 Caster Assembly Drawing ...

Page 45: ...45 Spindle Assembly Drawing 1 1 4 Spindle 3 4 Spindle 1 Spindle 1 2 Spindle 30mm Spindle ...

Page 48: ...48 Cabinet and Base ...