10

Each half of the aluminum fence should be adjusted

as close to the cutterhead as possible without inter-

fering with it. Each can be moved independently de-

pending on the type of work to be done:

4.

Loosen the knob (D) on the connection plate

and slide aluminum fence (E) to position, Figure 16.

Retighten knob (D).

WORK HOLD-DOWNS & SAFETY SHIELD

Two hold-downs and one safety shield are included

with the shaper. One hold-down (A) presses stock

down upon the table, the other (B) keeps it pressed

against the fence. These can be mounted to the hold-

down base (C), Figure 17, by the use of wing-nut

blocks (D). The safety shield (E) can be mounted to

either of the hold-down pieces as shown.

FIGURE 17

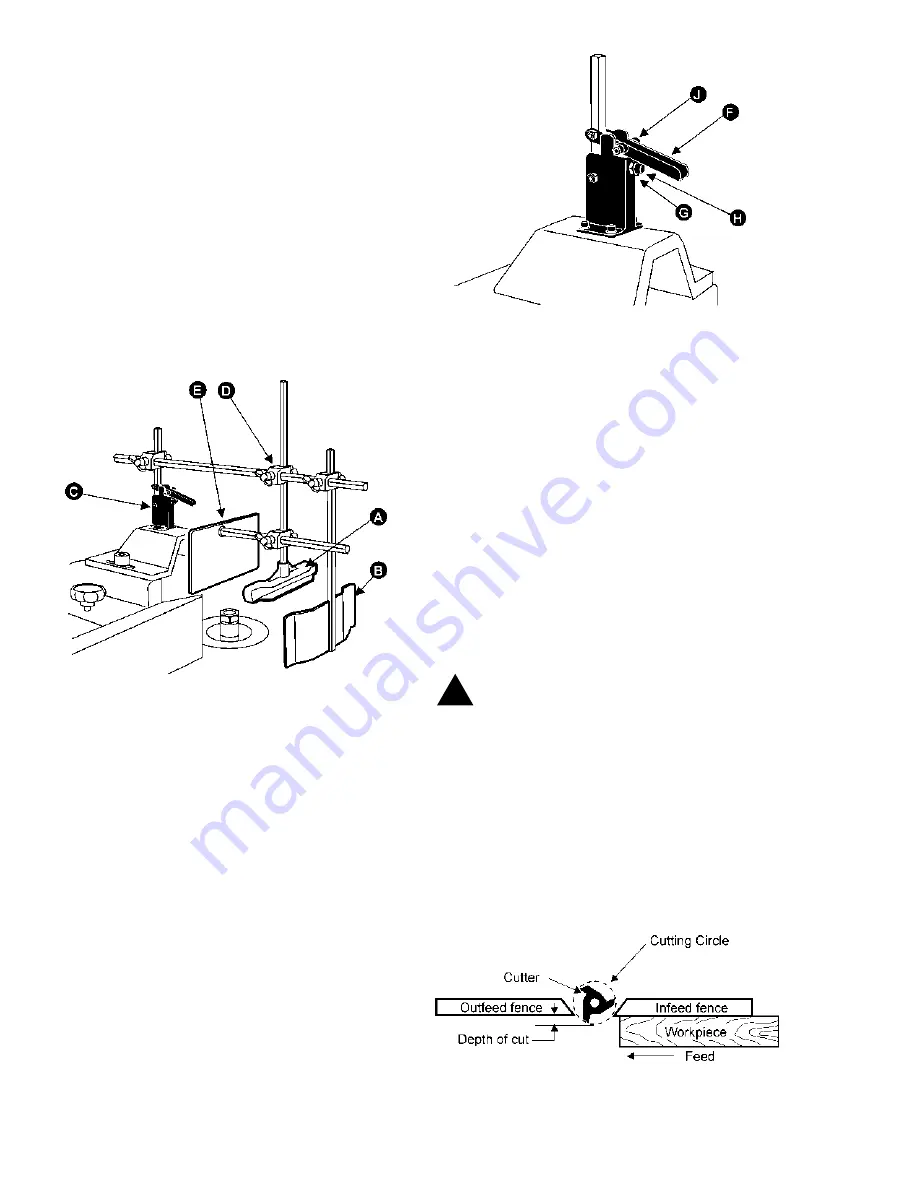

The hold-down base is factory adjusted to maintain

vertical positioning of the rod. However, if adjustment

is ever necessary, raise the handle (F) and loosen

nut (G) with a wrench. Then turn the socket head

screw (H) with an allen wrench, in or out until the rod

is vertical. See Figure 18. When satisfied, re-tighten

the nut (G). Loosen the soc. hd. screws (J) on the

handle and adjust the eccentric washers behind them

so that the handle can be lowered all the way but still

maintain a degree of tightness. Re-tighten screws.

FIGURE 18

When changing cutters, simply lift handle on hold-

down base (F), Figure 18, and flip entire assembly

back out of the way.

OPERATION

Always release the main spindle from the lock knob

before starting machine (see Figure 10).

Your shaper is equipped with pushbutton magnetic

controls. A start button, power indicator, reversing

switch, and emergency stop are all located on the

front of the machine.

To reverse the rotation of the spindle, simply shut off

the motor and engage the reversing switch.

CAUTION:

NEVER attempt to reverse the ro-

tation of the spindle while the motor is running.

SHAPING WITH THE FENCE

Using the fence is the safest and most satisfactory

method of shaping, and should always be used when

the work permits. Almost all straight work can be

used with the fence.

1.

For normal work, where a portion of the origi-

nal edge of the stock is not touched by the cutter,

both the infeed and outfeed fence are in a straight

line, Figure 19.

FIGURE 19

!

Summary of Contents for 29

Page 1: ...Instruction Manual Parts List M 0460218 800 274 6848 www powermatic com WOOD SHAPER Model 29 ...

Page 17: ...17 Fence Assembly 29 Shaper ...

Page 19: ...19 Spindle Assembly 29 Shaper ...

Page 21: ...21 Shaper Body Mitre Gauge Assemblies 29 Shaper ...