9

Tool Support

The tool support (shown in Figure 5), is designed to

allow adjustment for height, position on the bed, and

angle to the work. Your 3520A lathe comes standard

with the 14" tool support. Other supports are

available; consult the "Optional Equipment" list on

page 24.

Periodically the tool rest should be disassembled and

the parts cleaned and oiled to provide free movement

of the parts to insure good clamp action.

Spindle

The spindle bearing preload is set at the factory for

general turning applications. There should be no "end

play" of spindle looseness along its axis. If any

looseness ever occurs it may be removed by

tightening the bearing lock nut on the left end of the

spindle. Be very careful not to overtighten the lock

nut or the spindle bearings will overheat. It should be

tightened just enough to remove the end play and the

spindle should rotate very freely.

Speed Range Adjustment

To provide the maximum horsepower to the spindle at

the very slow speeds, set the drive belt in the low

range.

To change speed ranges, open the access door in

front of the headstock, loosen the pivot lock handle

located in the motor tension slot, raise the motor up

by lifting up on the motor plate handle and relock the

lock handle to hold the motor up. There should be

sufficient slack in the belt to reposition it to the other

step. Loosen the tension lock handle and lower the

motor to tension the belt. Be sure that the Poly-V

grooves of the belt seat properly in the corresponding

groove of the pulley. Do not overtension; a very light

pressure on the motor plate handle is adequate to

prevent belt slippage.

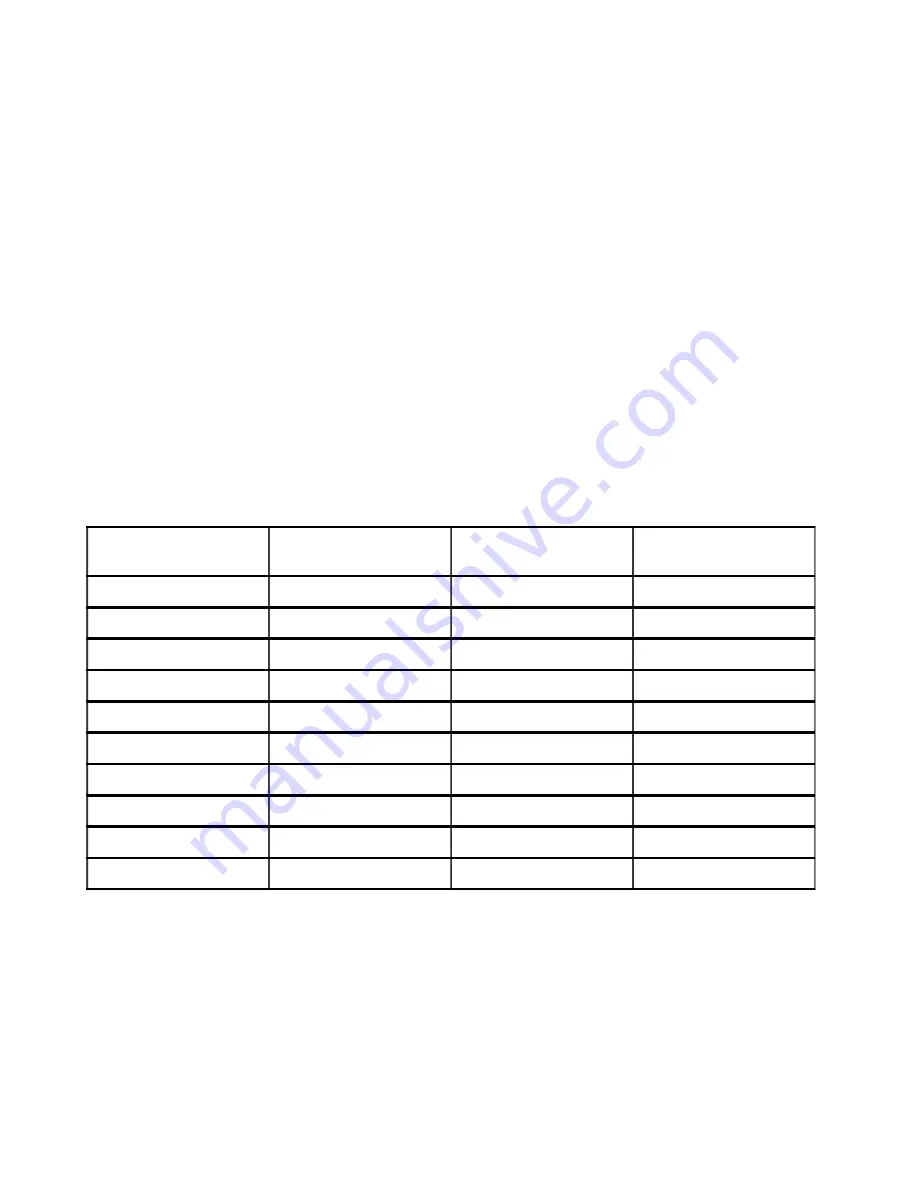

TABLE 1: WOOD TURNING LATHE SPEEDS

DIAMETER OF WORK

ROUGHING RPM

GENERAL CUTTING

RPM

FINISHING RPM

Under 2"

1520

3000

3000

2 to 4"

760

1600

2480

4 to 6"

510

1080

1650

6 to 8"

380

810

1240

8 to 10"

300

650

1000

10 to 12"

255

540

830

12 to 14"

220

460

710

14 to 16"

190

400

620

16" to 20"

175

325

500

20" to 24"

175

260

400

Summary of Contents for 3520A

Page 20: ...20 Headstock Assembly 3520A Lathe ...

Page 22: ...22 Stand Bed Assembly 3520A Lathe ...

Page 24: ...24 OPTIONAL ACCESSORIES Indexer Bed Extensions 3520A Lathe ...

Page 28: ...28 ELECTRICAL SCHEMATIC 3520A Lathe ...

Page 30: ...30 ELECTRICAL SCHEMATIC 3520A Lathe with Remote Switch Optional ...

Page 31: ...31 ELECTRICAL SCHEMATIC 3520A School Lathe 1352002 ...

Page 32: ...32 ELECTRICAL SCHEMATIC 3520A School Lathe 2330009 Kit ...