18

RESAWING

1.

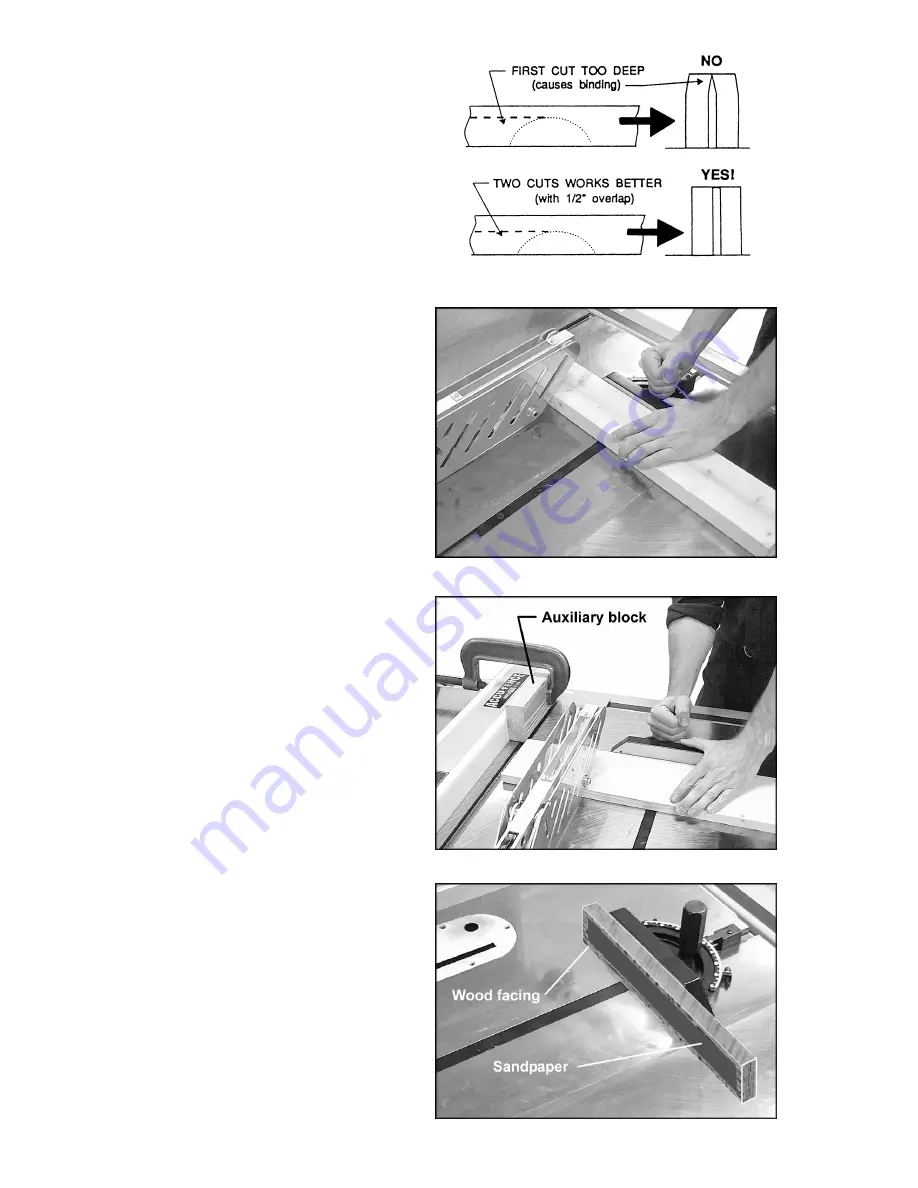

Resawing is a ripping operation in which thick

boards are cut into thinner ones. Narrow boards up

to 3" can be resawed in one pass. Wider boards up

to 6" must be resawed in two passes.

2.

In resawing wider boards, adjust the blade height

so as to overlap the two cuts by 1/2" as shown in

Figure 28. Too deep a first cut can result in binding

and possible kickbacks on the second cut. Always

use the same side of the board against the fence for

both cuts.

CROSSCUTTING

1.

Crosscutting is where the workpiece is fed cross

grain into the saw blade using the mitre gauge to sup-

port and position the workpiece. See Figure 29.

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless an

auxiliary block is clamped to the front of the blade

area such that the cutoff piece comes free of the block

before cutting starts. See Figure 30. Length stops

should not be used on the free end of the workpiece

in the cutoff area.

2.

Do not crosscut workpieces shorter than 6". Be-

fore starting a cut, be sure the mitre gauge is se-

curely clamped at the desired angle. Hold the

workpiece firmly against the table and back against

the miter gauge. Always use the saw guard and split-

ter and make sure the splitter is properly aligned.

2.

For 90 degree crosscutting, most operators pre-

fer to use the left-hand mitre gauge slot. When using

it in this position, hold the workpiece against the

gauge with the left hand and use the right hand to

advance the workpiece. When using the right hand

slot for mitre and compound crosscutting so that the

blade tilts away from the gauge, the hand positions

are reversed.

3.

When using the mitre gauge, the workpiece must

be held firmly and advanced smoothly at a slow rate.

If the workpiece is not held firmly, it can vibrate caus-

ing it to bind on the blade and dull the saw teeth.

4.

To improve the effectiveness of the mitre gauge

in crosscutting, some users mount an auxiliary

wooden extension face (with a glued-on strip of sand-

paper) to the mitre gauge as shown in Figure 31.

5.

Provide auxiliary support for any workpiece ex-

tending beyond the table top with a tendency to sag

and lift up off the table.

FIGURE 28

FIGURE 29

FIGURE 30

FIGURE 31

Summary of Contents for 72A

Page 21: ...21 FIGURE 38 FIGURE 37 ...

Page 27: ...27 Stand Assembly Model 72A ...

Page 29: ...29 ARBOR Model 72A ...

Page 31: ...31 Trunnion Model 72A ...

Page 33: ...33 Splitter Guard Assembly Model 72A ...

Page 34: ...34 ELECTRICAL SCHEMATIC Model 72A ...

Page 35: ...35 ELECTRICAL SCHEMATIC Model 72A ...

Page 36: ...36 ELECTRICAL SCHEMATIC Model 72A ...

Page 37: ...37 ...

Page 38: ...38 ...