14

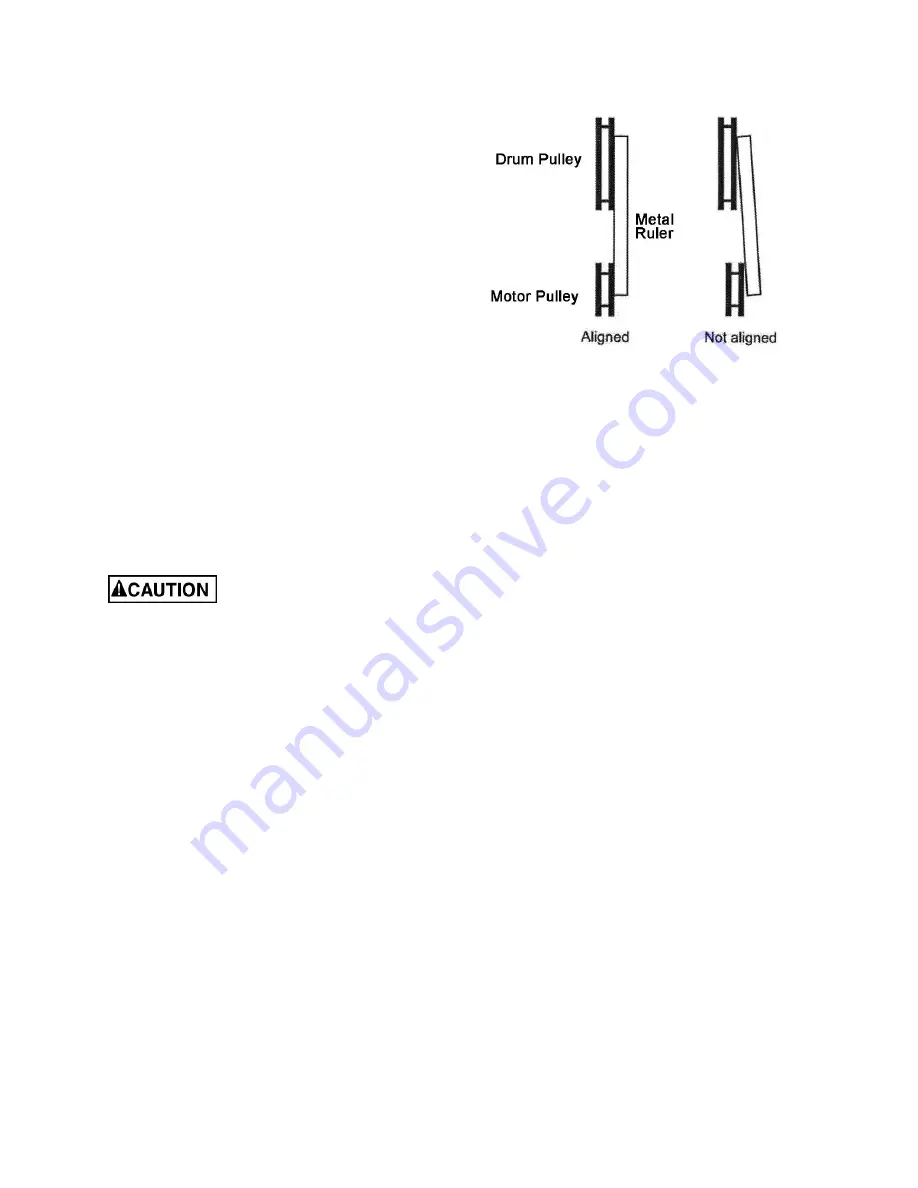

Pulley Alignment

The drum and motor pulleys must be in line so that

the belts are straight. To check this:

Place a straight edge, such as a metal ruler,

against the flat sides of the motor pulley and a

drum pulley (Fig. 18).

If the straight edge does not lie flush on the flat

sides of the pulleys, loosen the set screw on the

motor pulley (Fig. 17).

Move the motor pulley on the shaft until the straight

edge lies flush on both pulleys.

Tighten the set screw.

Figure 18

Changing Belts

The drums are heavy – use

an assistant to change belts.

Adjust the motor to allow slack in the belts, and

remove the two belts from around the motor

pulley. Belts should always be replaced as a

matched set.

Remove the four bolts holding the front drum to

the sides of the cabinet, and lift the front drum

out of the machine.

On the rear drum, loosen the two bolts at the

right side of the drum, but do not remove them.

Completely remove the two bolts that hold the

left side of the drum to the cabinet, and shift the

drum toward the right side. The left end of the

drum should come clear of the cabinet.

Remove the old belts and place the new belts

around the drum pulley. Reinsert the two bolts at

the left end of the drum and tighten firmly.

Retighten the two bolts at the right side of the

drum.

Check and adjust the tension of the new belts

before operating.

Summary of Contents for DDS-225

Page 26: ...26 Motor Cabinet Assembly DDS 225 ...

Page 28: ...28 Gearbox Assembly DDS 225 Drum ...

Page 37: ...37 Gearbox Assembly DDS 237 ...

Page 39: ...39 Wiring Diagram DDS 225 Sander ...

Page 43: ...43 Notes ...