7

Assembly

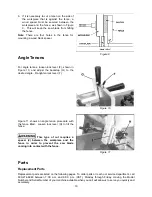

Refer to Figure 1.

1. Insert the

handwheel assembly

(F) into the

clamp bracket

(B) and secure with the

lock

handle

(A) on the clamp bracket.

2.

Attach the

clamp bracket

(B) to the back of

the fence (G) using two M10 x 25

socket head

cap screws

(D) and M10

lock washers

(E

).

3.

Attach the handles (C) to the clamp

bracket

(B).

Note:

There are two slots on the underside of the

tenoning jig. For the JTSA-10XL, 66 and 64A JET

& Powermatic left tilt saws, mount the slide (H)

into the left slot (farthest from the fence). A 4 mm

hex wrench (provided) is required.

Alignment

Disconnect saw from power

source before making adjustments to the

tenoning jig.

To align the tenoning jig:

1. Place the jig guide into the saw's left miter

gauge slot.

2. Using a square (A, Fig. 2), check to see if the

fence is 90 degrees to the saw table. To

make an adjustment to the fence, loosen the

lock handle (B), adjust the fence to the

90-degree position and tighten lock handle.

3. When the fence is 90 degrees to the table,

tighten setscrew (C) until it bottoms. See

Figure 2. Setscrew (C) acts as a positive stop

and allows you to quickly position the fence

back to the 90-degree position after it has

been tilted.

Figure 1

Figure 2

Summary of Contents for JTG-10Q

Page 12: ...12 Exploded View ...