If the fuel is natural gas

* If natural ventilation system is used.

** Ventilated airing system is used.

*** Bottom value shows the clean

air input up shows the air output.

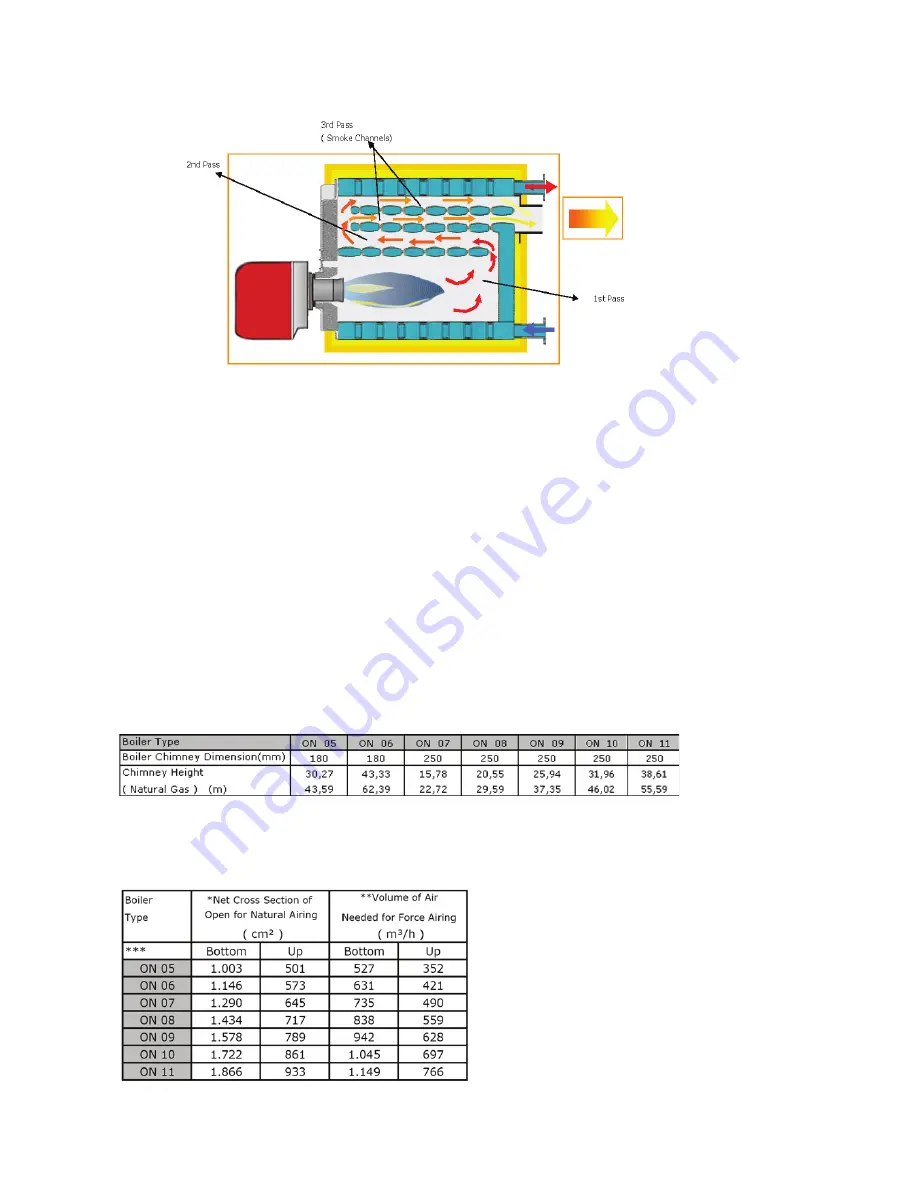

Cast Iron Sections with High Efficiency Design :

3 draught design forces the flue gas to circulate inside the body of the boiler three times before the chimney exit, transferring

all usefull energy to the water inside the sections. The optimized combustion chamber combined with perfect heat insulation

provides maximum fuel efficiency.

The combustion room of the boiler is positive pressure. Boiler is working under horizontal 3 pass principal.

Boiler Room Ventilation :

There are three reasons for fresh air in boiler rooms.

1.The air needed for the burning in the boiler.

2.The air needed for prevention of dirt and dust,for releasing the gases and fuel to put out.

3.The air needed for overheating in the boiler room.

Ventilation for first two reasons are continously needed.The third one is needed especially for the boilers which

are working on summer time.

Maximum temperature for the boiler room must be 32 °C and boiler room must be protected against freezing.

13