11

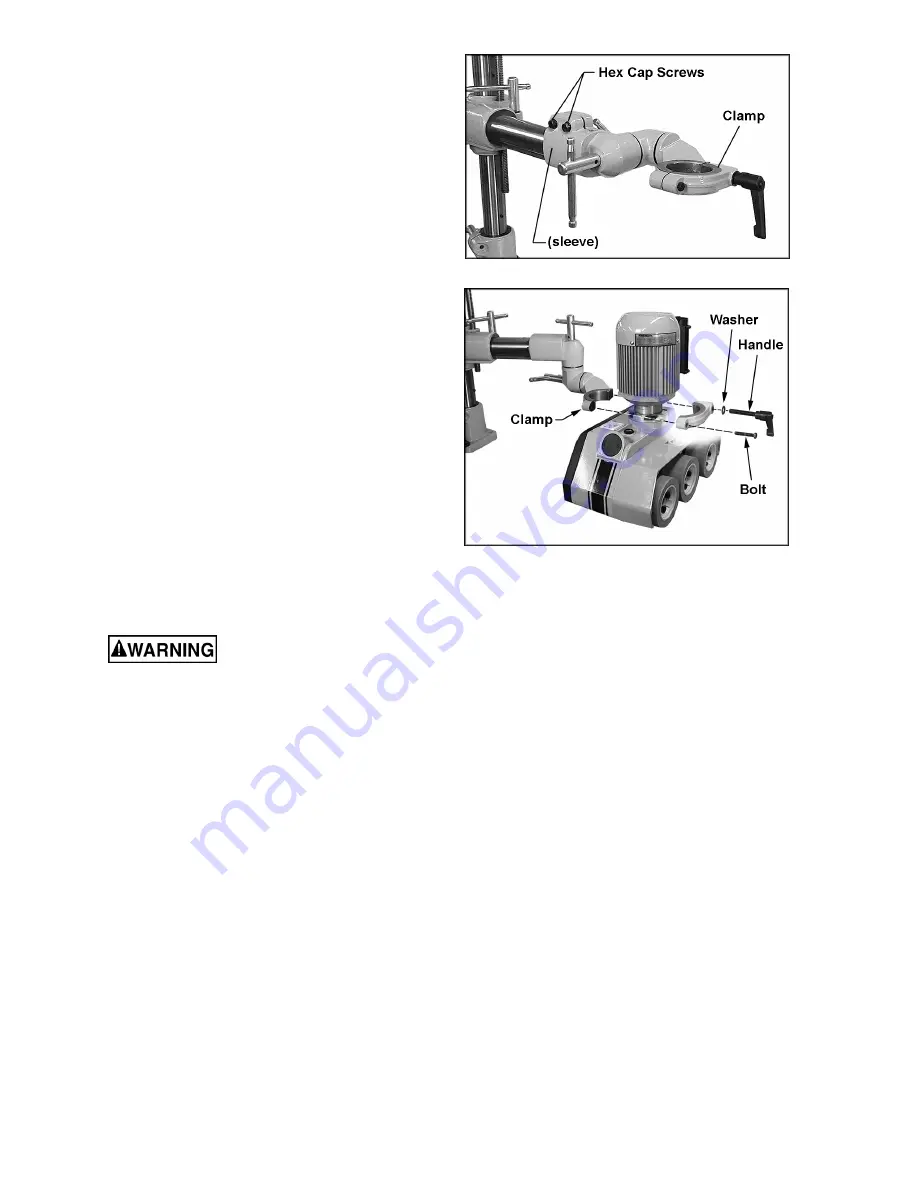

17. Mounting the feeder body may be easier if

you loosen the two hex cap screws (shown

in Figure 8) and rotate the over arm cone

assembly so that the clamp is toward the

bottom, as shown in Figure 9. Loosen the

handles and rotate the cones as needed to

get the clamp in position. Re-tighten the

screws and handles before mounting the

feeder body.

18. Unscrew the bolt and the handle (Figure 9)

from the clamp, and remove the outer half of

the clamp.

19. Position the neck of the stock feeder into the

inner half of the clamp, then attach the outer

half of the clamp. Re-install the bolt and

handle and tighten both of them gradually

and in turns, until the clamp is evenly tight

over the stock feeder neck. NOTE: The

seam between the two halves of the clamp

will not close entirely.

The handle (Figure 9) is adjustable. To

tighten it, rotate the handle clockwise, then

lift

out

on

the

handle,

rotate

it

counterclockwise on the pin and release it,

making sure it re-seats itself on the pin.

Continue this procedure until tight. (This

adjustable feature allows the handle to be

re-positioned at any time while remaining

tight.)

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The PF-series Feeders are available in voltages

ranging from 115 to 460, depending on the

model you purchased. Make sure the voltage of

your power supply matches the specifications on

the motor plate of the stock feeder.

The Stock Feeder is not supplied with an

electrical plug. You may either connect an

appropriate UL/CSA listed plug, or “hard-wire”

the machine directly to a service panel.

If the stock feeder is to be hard-wired to a panel,

make sure a disconnect is available for the

operator. Also make sure the fuses have been

removed or the breakers have been tripped in

the circuit to which the stock feeder will be

connected. Place a warning placard on the fuse

holder or circuit breaker to prevent it being

turned on while the machine is being wired.

Figure 8

Figure 9

The stock feeder must comply with all local and

national codes after being wired.

This machine must be grounded. In the event of

a malfunction or breakdown, grounding provides

a path of least resistance for electric current, to

reduce the risk of electric shock to the operator.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor, with insulation having an outer

surface that is green with or without yellow

stripes, is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipment-

grounding conductor to a live terminal.