14

General Operating Instructions

1. Make sure all handles on the stock feeder

and the feeder mounting assembly are tight

before operating.

2. The stock feeder should be used in

conjunction with a fence on your auxiliary

machine. The fence should be securely

fixed.

3. The rollers must grip the offcut, as well as

the part of the workpiece still being fed.

Also, the rollers should be set parallel to the

table or fence for proper feed.

4. On some machines, such as a shaper or

jointer, the stock feeder can be mounted so

that the rollers exert pressure from the top,

or mounted edgewise so that the rollers

exert pressure from the side, or mounted at

an

intermediate

angle

for

beveled

workpieces.

5. The feed rollers have a spring suspension

which will exert the necessary pressure

against the workpiece. This pressure

increases

automatically

with

feed

resistance, so that a workpiece of varying

thickness can be fed through the stock

feeder without adjustments.

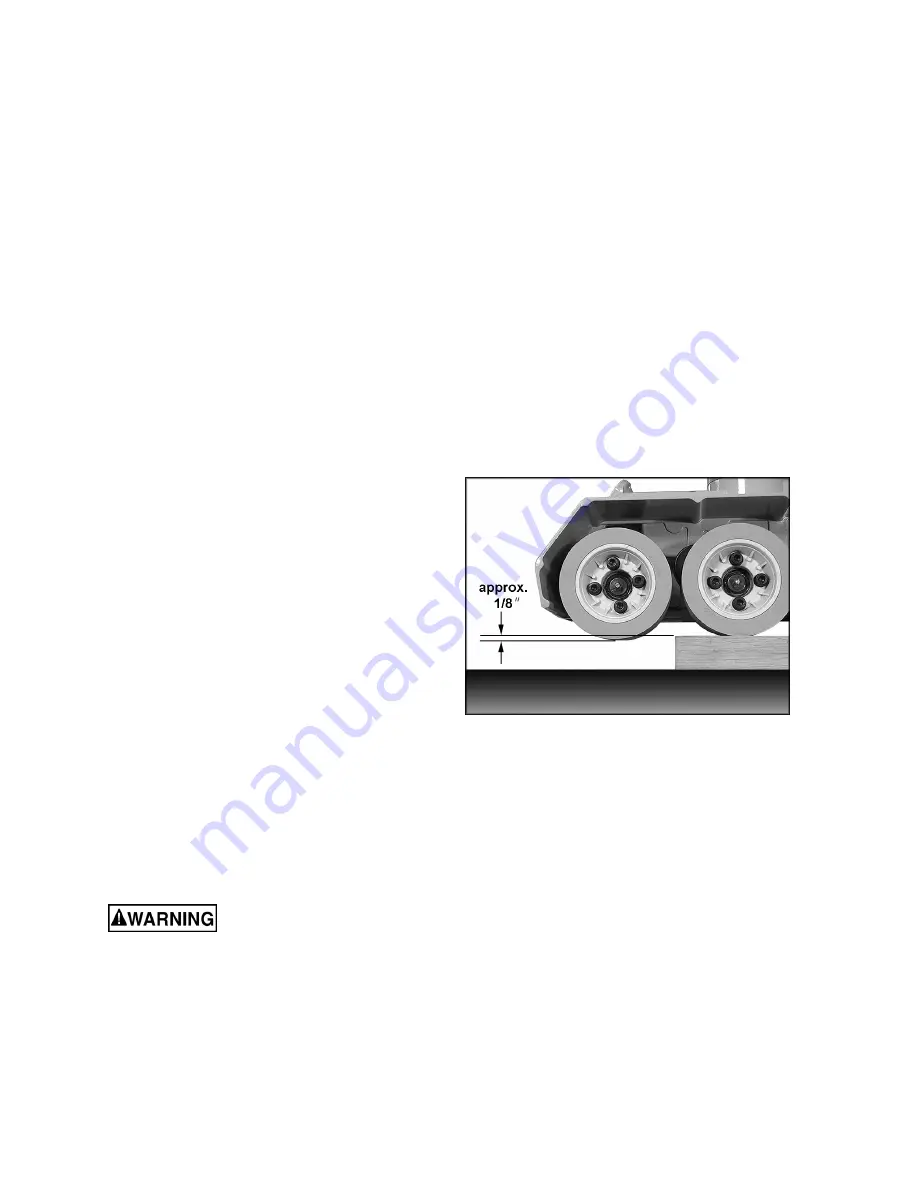

6. When used in horizontal position, the stock

feeder should be adjusted for height so that

the distance between the table and the feed

rollers is approximately 1/8

”

(3mm) less than

the thickness of the workpiece. See Figure

17.

7. Shaping hardwood with the stock feeder

may increase the friction between workpiece

and table. Keep the work table rust-free and

smooth, by using paste wax or other

necessary means.

8. Various configurations are possible with

your Stock Feeder, depending upon your

auxiliary machine and the type of work

being done. What is important is that the

feeder is positioned in the

most effective

and

safest manner

for the work being

done.

Although the stock feeder

when properly used will greatly reduce the

chance of workpiece kickback, there is still a

potential for kickback. Never stand directly

in the path of the workpiece as it passes

under the stock feeder rollers.

When Used with a Shaper

1. The gap between the fences for the cutter

should be as small as possible.

Figure 17