12

NOTE: The infrared sensor on the dust collector

has a 120° line-of-sight angle. See Figure 12.

Outside of this angle, the remote control may not

be effective.

Figure 12

Setting the Timer

(1-Phase Models)

While the machine is running, press the TIME

button to activate the timer. Each time the button

is pressed and released, the run time is

incremented on the digital display by one minute

and can be set up to 99 minutes.

If the TIME button is pressed and held, the time

will scroll up to 99 minutes, then start again at

00. Release the button when the desired set

time is reached. The dust collector will run for

the amount of time displayed on the digital

display. If you scroll past 99 and release the

button at 10, for example, the machine will run

for ten minutes, not 110 minutes.

If the OFF button is pressed while machine is

running with the timer engaged, the machine

turns off and the timer is disengaged; i.e., when

the machine is restarted, the timer must be

reset.

Connecting the Dust Collector to a

Machine

Use the proper type hose to connect the dust

collector to the machine being operated.

Dryer

vent hose is not acceptable for this purpose.

Contact your nearest Powermatic distributor for

a full line of Dust Collector hoses and

accessories. You can customize your installation

and obtain maximum performance with dust

hoods, hoses, clamps, fittings, and blast gates.

Maintenance

Never perform maintenance

on this machine before turning it OFF and

removing plug from power source. Failure to

comply may cause serious injury!

Cleaning the Filter Bags

Wearing a particle mask or

respirator for protection against fine dust

particles during cleaning is highly

recommended.

During first use and after cleaning, the filter bags

may allow some dust to escape. This is normal

and will stop after a short period of time.

Clean both the filter and collector bags

frequently to keep the collector's performance at

its optimum. To clean:

1. Disconnect machine from the power source.

2. Unhook the filter bag from the hanger.

Shake the bag so that the majority of the

dust falls into the collector bag.

3. Loosen the retaining strap, and remove the

filter bag from the housing.

4. Turn the bag inside-out and clean.

5. Turn the bag outside-in and re-attach to the

housing using the retainer strap to secure.

Removing the Collector Bags

1. Disconnect machine from the power source.

2. Remove the collector bag by pushing the

ring of the collector bag upwards and pulling

the bag out at an angle.

3. Empty the contents into an appropriate

container.

4. Turn the bag inside-out and clean.

5. Turn the bag outside-in and insert into the

housing.

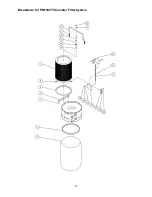

Cleaning the Canister Filters

Clean the canister filters frequently to keep the

collector's performance at its optimum. To clean

the filter, turn the handle a couple of rotations so

the dust falls into the clear plastic bag. Properly

discard the plastic bag.

Motor

Make frequent inspections of the motor fan and

blow out (with low pressure air hose) or vacuum

any accumulation of foreign material in order to

maintain normal motor ventilation.