15

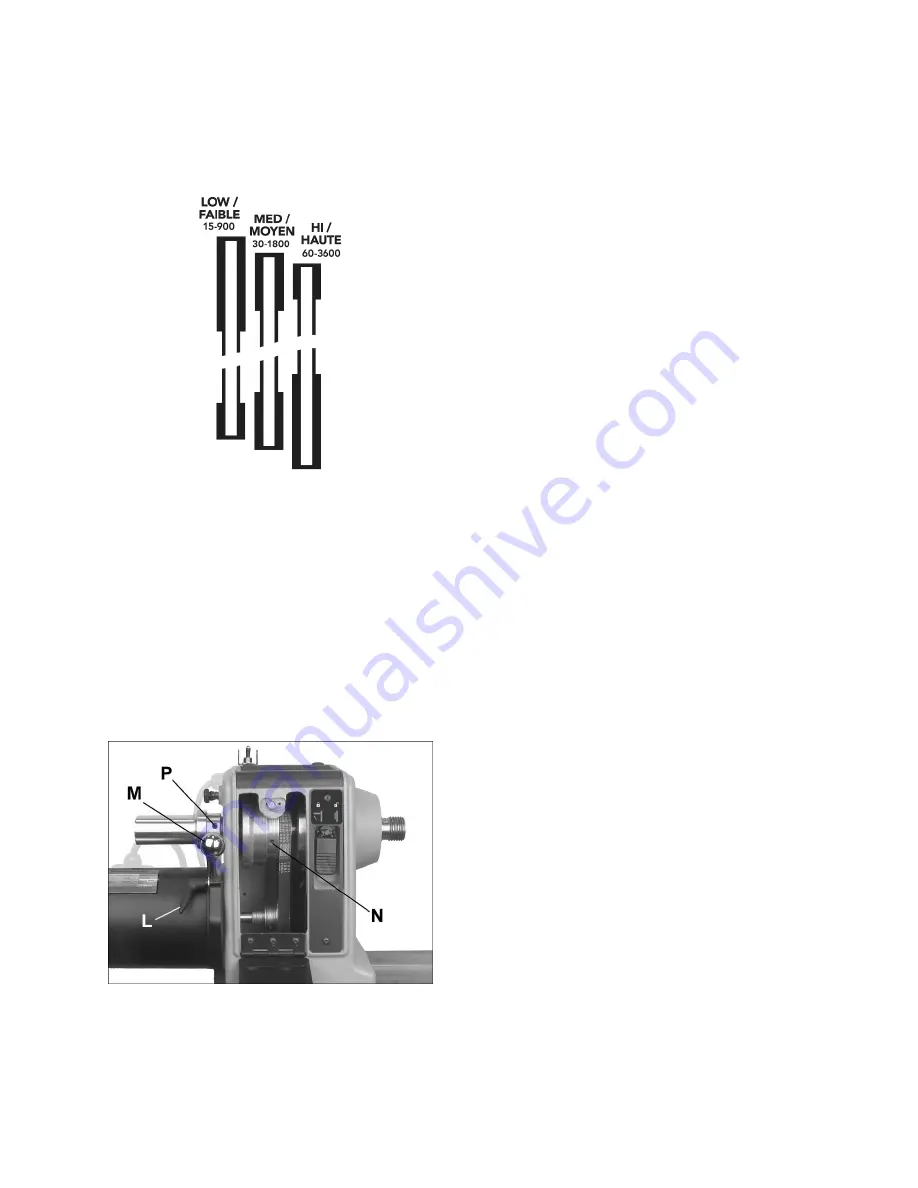

5. Loosen pivot lock handle (L, Figure 8-9) and

lower motor to tension belt. Be sure that V-

grooves of belt seat properly in corresponding

grooves of sheave. Do not overtension; a very

light pressure on the tension handle (M) is

adequate to prevent belt slippage.

6. Tighten pivot lock handle (L).

Figure 8-8

8.9

Sheave and belt alignment

1. The motor and spindle sheaves are aligned by

the manufacturer, but if any service is

performed that affects their alignment it is very

important that they be realigned. To realign

them, loosen two set screws on spindle sheave

(one is shown at N, Figure 8-9) with a hex key,

and nudge spindle sheave into proper position.

Retighten both set screws.

2. When sheaves and belt are properly aligned,

there should be no unusual pulsing sounds or

noise coming from the belt.

Figure 8-9: sheave/belt alignment

8.10

Sheave/drive belt replacement

IMPORTANT:

Replacing spindle sheave or belt can

be a challenging procedure. If you do not feel

confident performing this action, take the headstock

to an authorized Powermatic service center.

1. Disconnect

lathe

from power source.

2. Loosen lock handle (L, Figure 8-9) and lift

handle (M) to raise motor.

3. Tighten lock handle (L) to hold motor in raised

position. Slip belt off lower pulley.

4. Loosen two set screws on handwheel (P, Figure

8-9) with a 3mm hex wrench, and unscrew

handwheel off spindle (NOTE: Left-hand

threads; rotate clockwise to loosen).

5. Tap left end of spindle with a rubber mallet, or a

steel face hammer against a block of wood, to

push it to the right, just enough to remove

sheave or belt. (

Never

use a steel face hammer

directly against spindle.) Prevent the top

sheave from being forced into the

sensor/encoder assembly; if necessary loosen

sheave set screws and slide it to the left.

6. If replacing sheave, loosen two set screws (N,

Figure 8-9), and slide sheave off spindle. Install

new sheave,

loosely

securing the two set

screws at first. Make sure the sheave is

oriented properly.

7. Push spindle back into place. Make sure the

sensor collar is positioned over the sensor for

the digital readout to function.

8. Check for any spindle play or “runout” at this

point. If it exists, see

sect. 13.0

.

9. Reinstall handwheel and tighten set screws (P,

Figure 8-9).

10. Align new sheave (see

sect. 8.9)

then tighten

two set screws (N, Figure 8-9) securely on

sheave.

11. Loosen lock handle (L) and allow motor to

lower. Do not over-tension; a very light pressure

on tension handle (M) is adequate to prevent

belt slippage.

12. Tighten lock handle (L).

Summary of Contents for PM2014

Page 27: ...27 15 1 1 PM2014 Headstock Assembly Exploded View ...

Page 30: ...30 15 2 1 PM2014 Bed Toolrest and Tailstock Assemblies Exploded View ...

Page 35: ...35 16 0 Electrical connections PM2014 Lathe cont next page ...

Page 36: ...36 cont ...

Page 38: ...38 This page intentionally left blank ...

Page 39: ...39 This page intentionally left blank ...

Page 40: ...40 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com ...