8

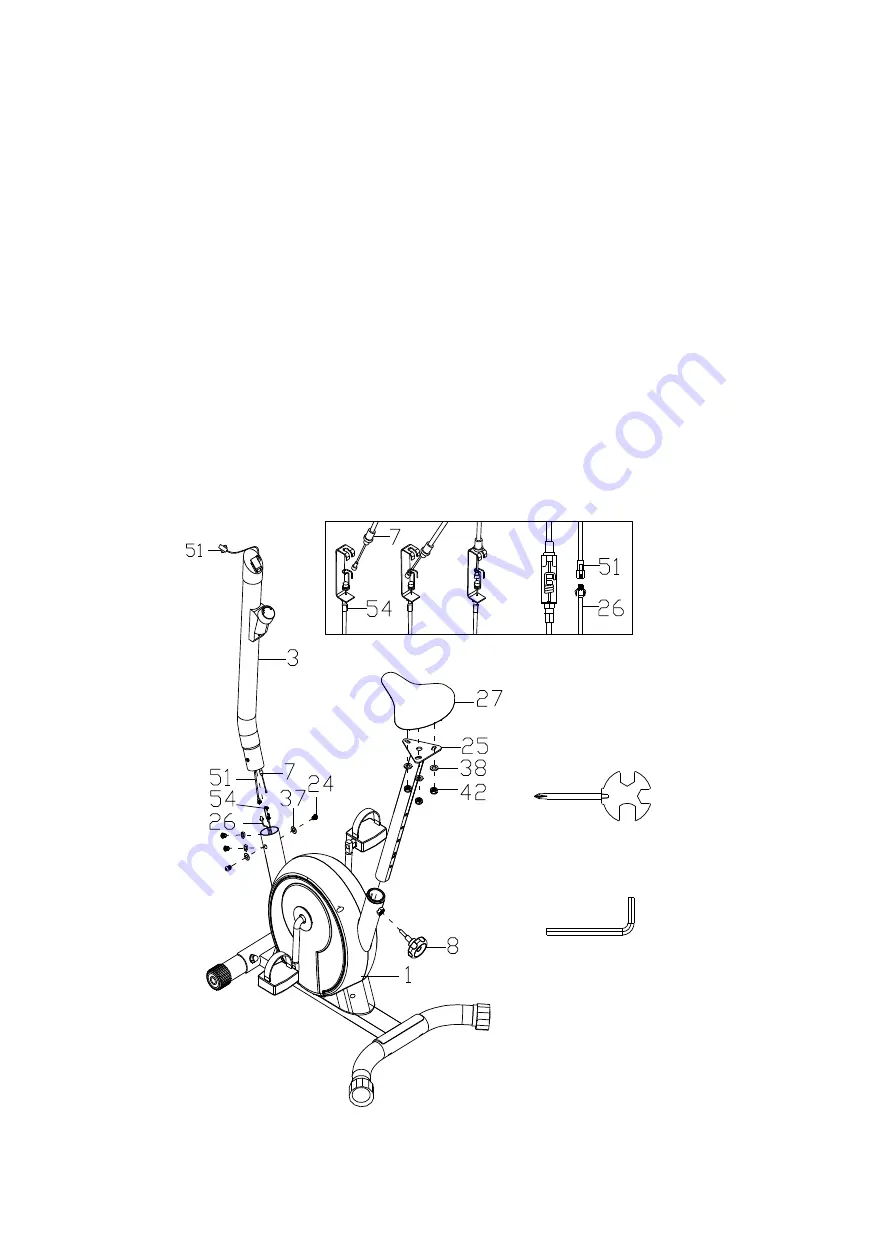

Step 3: Connect the tension control (7) with lower tension wire (54) as the photo.

Step 4: Connect the

middle wire (51) with sensor (26). Then fix the meter tube (3) to

the main frame (1) by 4 sets bolt M8*15 (24) and arc washer Φ8 (37)

Step 5

:

Fix the saddle (27) to the seat tube (25) by 3 sets flat washer Φ8 (38) and

locking nut M8 (42) which are attached on the saddle.

Step 6

:

Insert the seat post (25) to the seat post bellow and then fix to the main frame by

knob (8).

Multi Hex Tool with Phillips

Screwdriver S13-S14-S15 1PC

Allen Wrench

S6 1PC