2

The Model 2000TN trigger-pull top nailer is designed to bring Powernail quality and fl ooring

expertise to a pneumatic nailer. The Model 2000TN is designed for use with 1” and 1-1/4”, 20

gauge L-Cleat Powernails®.

INTRODUCTION

INDEX

LIMITED WARRANTY

POWERNAIL® Company, Inc. warrants to its customer, and to the fi rst end-use

purchaser of POWERNAIL Model 2000TN POWERNAILER purchased from an

authorized POWERNAIL distributor, that each serialized manufactured Model 2000TN

POWERNAILER by POWERNAIL®, for a period of 12 months from the date of purchase;

shall be free of defects in materials and workmanship and will meet POWERNAIL’S

specifi cations in eff ect at the time of product shipment. POWERNAIL will repair or

replace, at its option, any Model 2000TN POWERNAILER that does not conform to

this warranty. Claims must be made no later than fi fteen (15) days after the end of the

warranty period. POWERNAIL will perform all repair or replacements itself or through its

authorized contractors. POWERNAIL is not responsible for shipping, labor or other direct

or indirect costs. Damage caused by abuse, misuse, unusual or excessive wear is excluded.

Repair or modifi cation of the Products by unauthorized parties will void this warranty.

The customer is responsible for returning Products to POWERNAIL for verifi cation of

nonconformance. Warranties for Products not manufactured by POWERNAIL are limited

to warranties provided to POWERNAIL by the manufacturer of such product that are

assignable to customer.

THESE WARRANTIES AND REMEDIES ARE EXCLUSIVE OF ALL OTHERS,

EXPRESS OR IMPLIED. THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PURPOSE ARE EXPRESSLY EXCLUDED. IN NO EVENT SHALL

POWERNAIL’S LIABILITY FOR A WARRANTY CLAIM EXCEED THE PRICE PAID

TO POWERNAIL FOR THE NONCONFORMING PRODUCT, REGARDLESS OF THE

FORM OR BASIS OF THE CLAIM OR CAUSE OF ACTION.

Index.....................................

2

Warranty...............................

2

Safety Instructions................

3

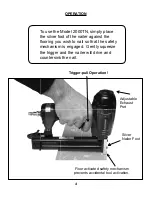

Operating the tool.................

4

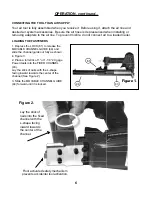

Air Supply.............................

7

Safety Labels........................

7

Maintenance.........................

7

Troubleshooting Chart..........

5

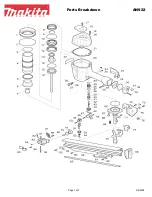

Parts List.........................

8

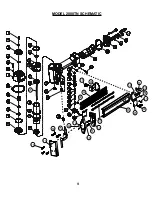

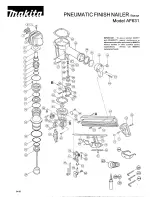

Schematic........................

9

Phone Support.....................

12

Web Site..............................

12

Powernail Company Info.....

12