4

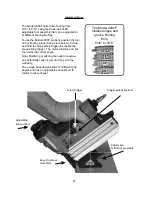

The Model 2000F nails down fl ooring from

5/16” to 9/16” using the Powernail FLEX

adjustable foot assembly that can be adjusted to

fi t different fl ooring profi les.

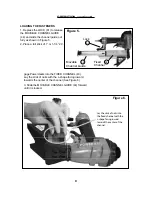

To use the Model 2000F, properly position the tool

on the fl ooring plank (See picture below). Pull up

and hold the black safety trigger to activate the

orange fi ring trigger. The nailer will drive and set

the nail at the correct angle.

Note: Modifying or altering the nailer in anyway

can potentially cause injury and may void the

warranty.

The unique body design allows for different grip

angles and has an adjustable exhaust port to

redirect nailer exhaust.

OPERATION

The Model 2000F

installs tongue and

groove fl ooring

from

5/16” to 9/16”

.

5/16"

(8 mm)

5/

16

"

3/8"

(9 mm)

3/

8"

1/2"

(12 mm)

1/

2"

1/

2"

.

.

.

.

.

.

.

.

.

9/16"

(14 mm)

Trigger-pull Activation!

Adjustable

Exhaust Port

Adjustable

FLEX Foot Assembly

Easy-to-remove

Gate Plate

Safety Trigger

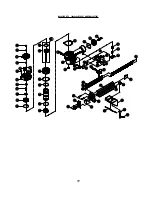

Summary of Contents for Powernailer 2000F

Page 11: ...11 MODEL 2000F SCHEMATIC A...