Figure 3

5

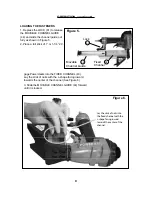

CONNECTING THE TOOL TO AN AIR SUPPLY

Your air tool is fully assembled when you receive

it. Before using it, attach the air line and desired

air system accessories. Be sure the air hose

is depressurized when installing or removing

adapters to the air line. To prevent misfi re, do not

connect air to a loaded nailer.

Figure 2

AIR HOSE

1. An automatic airline oilier is recommended but

oil may be added manually before every operation

or after about 8 hours of continuous use.

2. Place two (2) drops of air-tool oil in the air plug

as shown (Figure 3). If you are using an automatic

in-line oiler, check and add oil if necessary.

3. Turn your compressor on and set the

compressors pressure regulator to the proper

pressure. Normal operating pressure should be

adjusted between 70-110 psi based on fastener

and wood being used.

4. Connect the tool to the air supply (Figure 2).

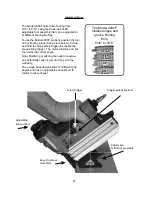

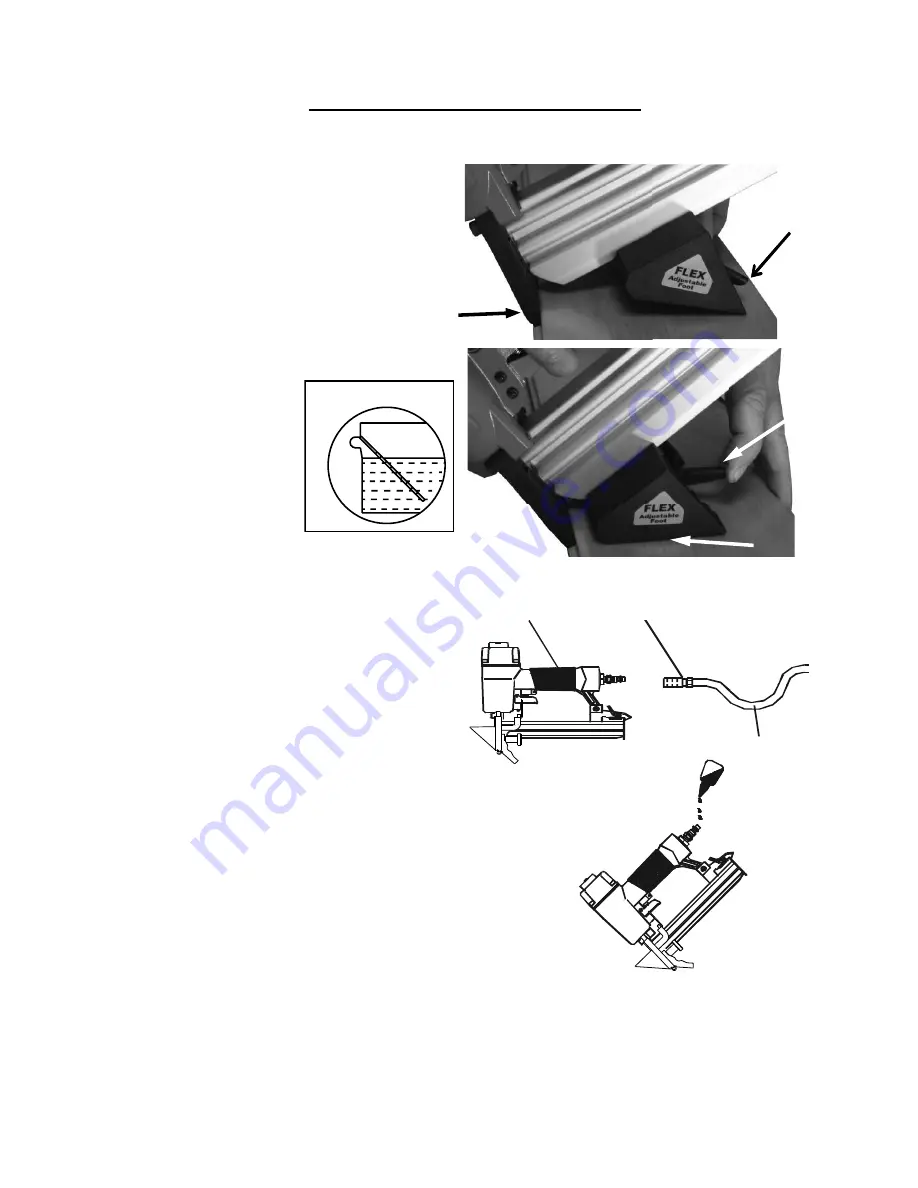

FOOT ADJUSTMENT / NAIL LOCATION

Flip the lever (1A) on the FLEX Foot to

one side so the FLEX Foot is free to slide

on the channel.

Using a sample of your fl ooring, slide the

FLEX Foot back on the channel and set

the nose of the nailer (1B) on top of the

fl ooring tongue.

Keeping the nose fl ush on the fl ooring

tongue, slide the FLEX Foot forward until

it lies fl at on the fl ooring surface (2A).

Flip the adjustment lever

and tighten it (2B) so the

FLEX Foot is locked in

place.

Always test fi re into your

sample wood to ensure

the nail is setting correctly

(Figure 1).

Adjust the FLEX Foot to your wood...

Nailer

Quick

Connector

1A

1B

2A

2B

Figure 1.

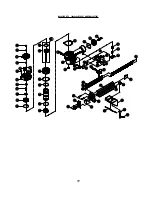

Summary of Contents for Powernailer 2000F

Page 11: ...11 MODEL 2000F SCHEMATIC A...