POWXQ5330

EN

Copyright © 2013 VARO

P a g e

|

8

www.varo.com

9.2

Dust and chip extraction

For integrated dust extraction, place the dust bag (20) on the sawdust ejector.

For external dust, you can use a vacuum cleaner hose.

The dust bag is only for a partial dust removal! It is designed to break the

dust extraction.

9.3

Clamping the work piece

Make sure the work piece can’t be catapulted. The clamp(11) is the most perfect gadget to

avoid this.

Press the work piece against the fence (4) and against the stop of the clamp

Tighten the clamp to secure the work piece.

9.4

Horizontal mitre angle

The horizontal mitre angle can be set in the range from -45° to 45°. The horizontal mitre angle

scale shows the currently set in degrees.

Loosen the locking knob (9) by turning it counter clockwise.

Push the lever downwards.

Rotate the saw table (5) to the required angle ( to the right or to the left). The required angle

can be read of the scale flute.

Release the lever.

Tighten the locking knob (9) clockwise.

9.5

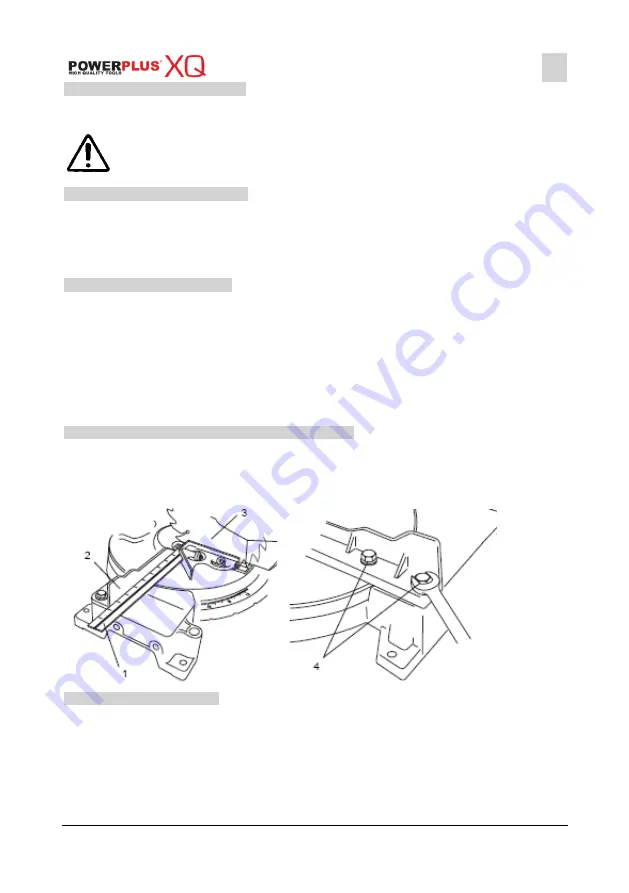

Adjustment of the saw blade and guide rail.

Position the saw in the lower position and block it with the blocking pin.

Now hold the try square (90°) against the guide rail and the saw blade. The latter must

make complete contact with the try square. If this is not the case, then you can adjust the

angle by moving the guide rail. To carry out this step, use the delivered key for loosening

the screws. Do not forget to re-tighten the screws afterwards.

9.6

Vertical bevel angle

The vertical bevel angle can be set in the rang of 0° to 45°. The vertical bevel scale shows the

currently set in degrees.

Remove the quick action clamp and move the moving part of the fence to the left side.

Loosen the locking knob (17), if tightened.

Swing the tool arm (13) with the handle (15) to the required angle.

Tighten the locking knob (17).