Cyberhawk-200M Installation

-

8 of 22 -

Doc. No: 202-003318-610 Rev A01

!

INSTALLATION

WARNING

HAZARD OF ELECTRIC SHOCK OR ARC FLASH

Risk of

Electric

Shock

Open or disconnect all power sources and “Lock out” prior to any

work being done on the electrical system

More than one disconnect may be required to de-energize the

equipment before servicing

Open or disconnect circuit from power-distribution system (or

service) of building before installing or servicing current-sensing

transformers (CTs)

Never leave CTs in powered circuit open circuited

Caution:

Do not assume but check that all power sources at the system

connection points are off using a properly rated voltage

indicating device (Multi-meter, etc) and “Locked out”

MOUNTING

Prior to Installation:

Prior to installation check the internal condition of the equipment as follows:

Equipment Voltage rating for the application (e.g. 600/480V, 208/120V)

Damaged or dislodged or loose components

Loose connectors or connections

Broken wires

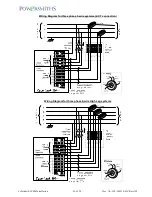

Mounting the Cyberhawk-200M-xP

Attach the mounting brackets to the

Cyberhawk-200M-

xP with supplied mounting bracket

hardware. One of two types may be supplied as illustrated.

Mount the unit to the wall in the required location with ¼” hardware appropriate for the

mounting surface material (Note: mounting hole is 5/16”).

Mounting the CT Interface Box (if supplied)

Attach the wall mounting brackets to the

CT Interface Box

with supplied mounting bracket

hardware as illustrated above

Locate and mount the unit to a wall in the required location with ¼” hardware appropriate for

the mounting surface material (Note: mounting hole is 5/16”)

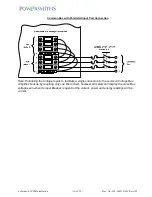

Note locate the CT Interface Box (if supplied) to allow for direct wire connections (without

splices) from the CTs to the terminals in the box

.

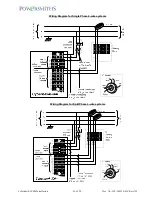

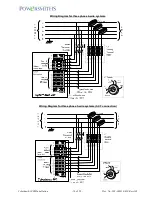

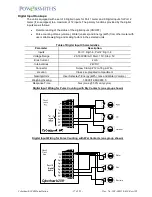

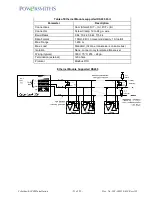

Installation of Branch Circuit Protection Devices

Install a Branch Circuit Protection Device (Fused Disconnect or Breaker) for each Bus to be

monitored following the specific manufacturer’s instruction and in compliance with the

relevant local and national electric codes*.

*Reference: NEC 2005 Article 408 Para: 408.52