Summary of Contents for Z1 PSZ133KWA

Page 3: ......

Page 19: ...16 Machine Troubleshooting...

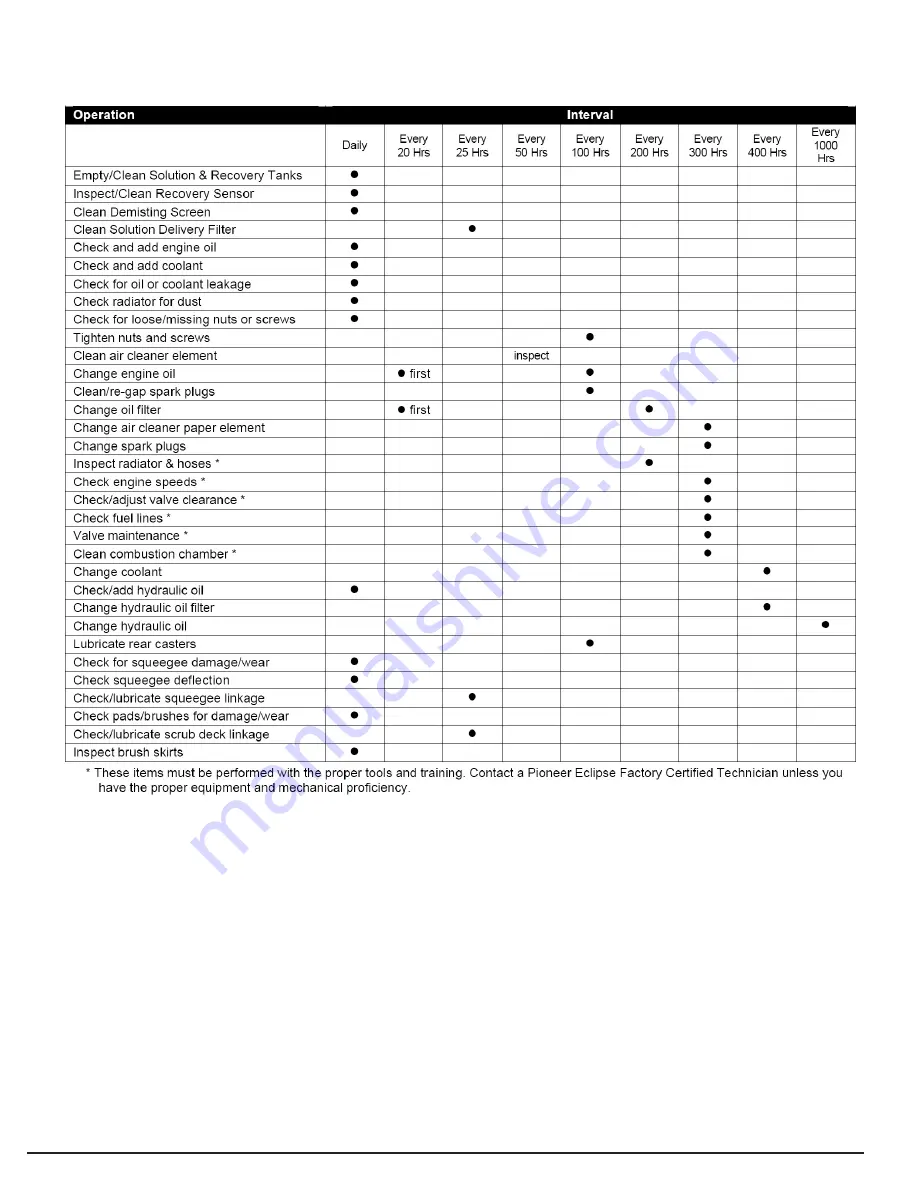

Page 20: ...17 Maintenance...

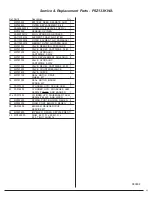

Page 27: ...Service Replacement Parts PSZ133KWA 031708 24...

Page 29: ...26 Wiring Schematic PSZ133KWA SAFE SENSE FOR MACHINES SERIAL NUMBER 62233 AND EARLIER 031708...

Page 30: ...27 Wiring Schematic PSZ133KWA ECO SENSE FOR MACHINES SERIAL NUMBER 62420 AND LATER 031708...

Page 32: ...29 Hydraulic Schematic PSZ133KWA 031808...

Page 33: ...30 Hydraulic Hose Connection Group PSZ133KWA 031808...

Page 35: ...32 Frame Wheel Group PSZ133KWA 031808...

Page 37: ...34 Power Group Engine PSZ133KWA 031808...

Page 39: ...36 Hydraulic Reservoir PSZ133KWA 031808...

Page 41: ...38 Airbox PSZ133KWA 031808...

Page 43: ...40 LP Regulator PSZ133KWA 031808...

Page 45: ...42 Scrub Deck Group PSZ133KWA 052308...

Page 47: ...44 Squeegee Lift Group PSZ133KWA 031808...

Page 53: ...50 Solution Tank PSZ133KWA 031808...

Page 55: ...Recovery Tank PSZ133KWA 52 030808...

Page 57: ...54 Engine Cover PSZ133KWA 031908...

Page 59: ...Squeegee 45 PSZ133KWA 56 031908...

Page 61: ...58 Control Panel Bulkhead Group PSZ133KWA 031908...

Page 63: ...60 Operational Controls PSZ133KWA 031908...

Page 67: ...64 Relay and Timer Group PSZ133KWA 031908...

Page 73: ...70...