- 52 -

5.3.2. DI Debounce Time

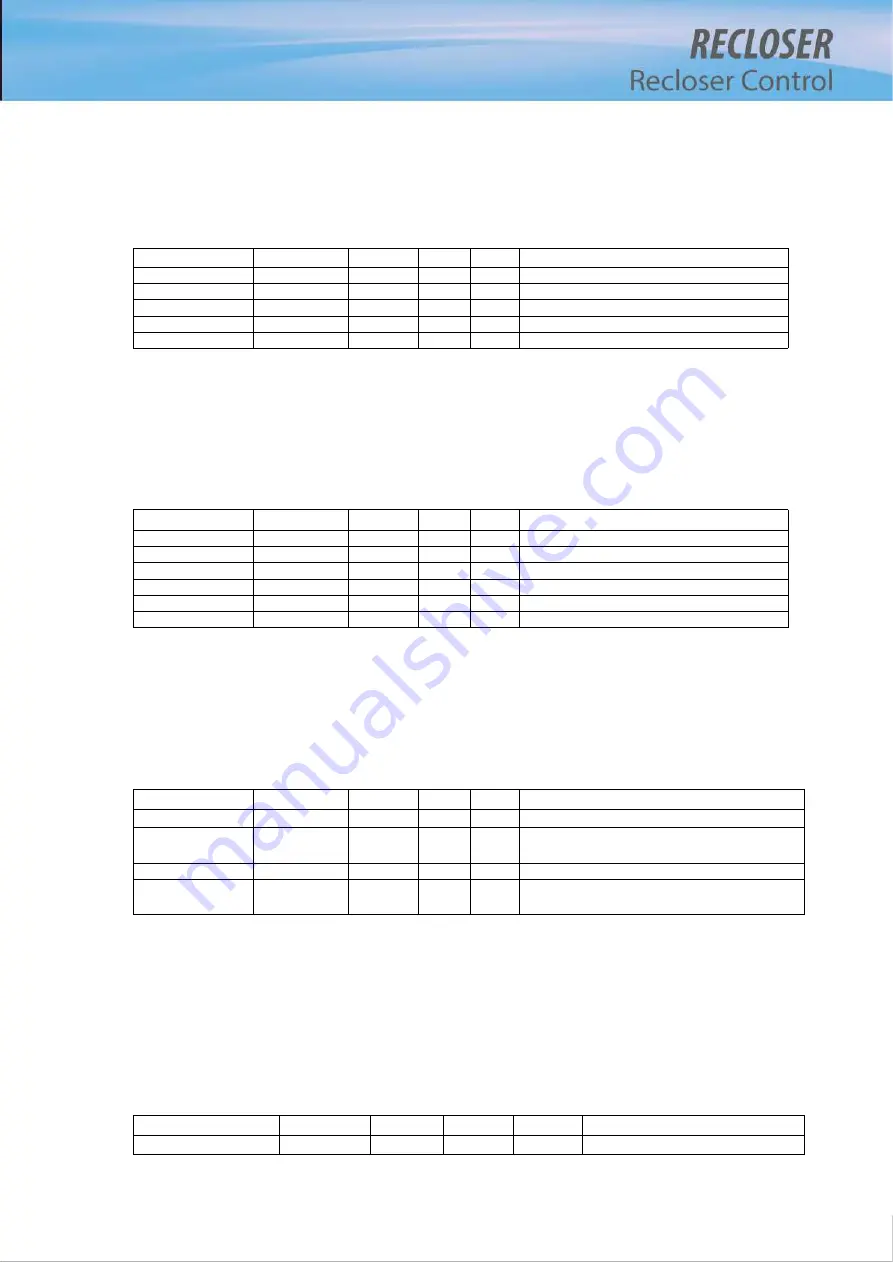

It is a menu to set debounce time to prevent DI Chattering. It is available to set on each channel.

During set time, DI status value should be kept to be considered with the changed value.

<Table 5-7> DI Debounce Setting

Item

Range

Default

Step

Unit

Explanation

DI_1

1~500

10

1

ms

DI 1’s debounce time setting

DI_2

1~500

10

1

ms

DI 2’s debounce time setting

DI_3

1~500

10

1

ms

DI 3’s debounce time setting

...

...

...

...

...

...

DI_10

1~500

10

1

ms

DI 10’s debounce time setting

The way to set is identical with 5.3.1

5.3.3. DO Pulse Width

It sets DO1~6’s on pulse output time.

<Tabel 5-8> DI Pulse Setting

The way to set is identical with 5.3.1

5.3.4. Backup Set / Clear

It is a menu operating switch operation count, Event data clear, Fault data and clear.

<Table 5-9> Backup Set / Clear

The way to set is identical with 5.3.1

5.3.5. Analog Gain Adjust

It is a menu to adjust analog voltage / current volume gain. EPIC-R300 is set in calibration

about voltage / current signal input from factory. However if measuring value is different

because of external sensor’s error, use the menu to adjust.

<Table 5-10> Analog Gain Adjust

Item

Range

Default

Step

Unit

Explanation

DO_1

10~2000

500

10

ms

DO 1’s pulse width time setting

DO_2

10~2000

500

10

ms

DO 2’s pulse width time setting

DO_3

10~2000

500

10

ms

DO 3’s pulse width time setting

DO_4

10~2000

500

10

ms

DO 4’s pulse width time setting

DO_5

10~2000

500

10

ms

DO 5’s pulse width time setting

DO_6

10~2000

500

10

ms

DO 6’s pulse width time setting

Item

Range

Default

Step

Unit

Explanation

Set Switch Cnt

0~65535

0

1

Set the number of switch operation

Clear Event

NO/YES

NO

Delete saved event information in backup

memory

Clear Fault

NO/YES

NO

Delete save fault information in backup memory

Clear Oper Count

NO/YES

No

Delete save operation information in backup

memory

Item

Range

Default

Step

Unit

Explanation

Ia Gain Adjust

10~2000

0

1

A

Adjust current Ia’s gain

Summary of Contents for RECLOSER

Page 1: ...User Manual Document Version 1 5 Feb 28 2019 http powersys kr http www powersys kr...

Page 14: ...8 3 5 Mechanical Performance and Size Weight 3 5 kg FRONT VIEW Figure 3 1 Front View...

Page 15: ...9 SIDE VIEW 343 00 310 00 91 00 Figure 3 2 Side View...

Page 16: ...10 TOP VIEW 84 0 260 0 225 0 1 0 0t Figure 3 3 Top View...

Page 17: ...11 REAR VIEW 180 0 120 0 Figure 3 4 Rear View...

Page 22: ...16 Controller PCB 215 00 103 90 121 10 112 50 112 50 235 00 205 00 Figure 3 8 Controller PCB...

Page 69: ...63...

Page 71: ...65 Example configuration file...

Page 73: ...67 2 TC Curve 1 4 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 1 2 3 4...

Page 74: ...68 3 TC Curve 5 8 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 5 6 7 8...

Page 77: ...71 6 TC Curve A D 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting A B C D...

Page 78: ...72 7 TC Curve E M 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting E K L M...

Page 79: ...73 8 TC Curve N T 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting N P R T...

Page 80: ...74 9 TC Curve V Z 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting V W Y Z...