- 56 -

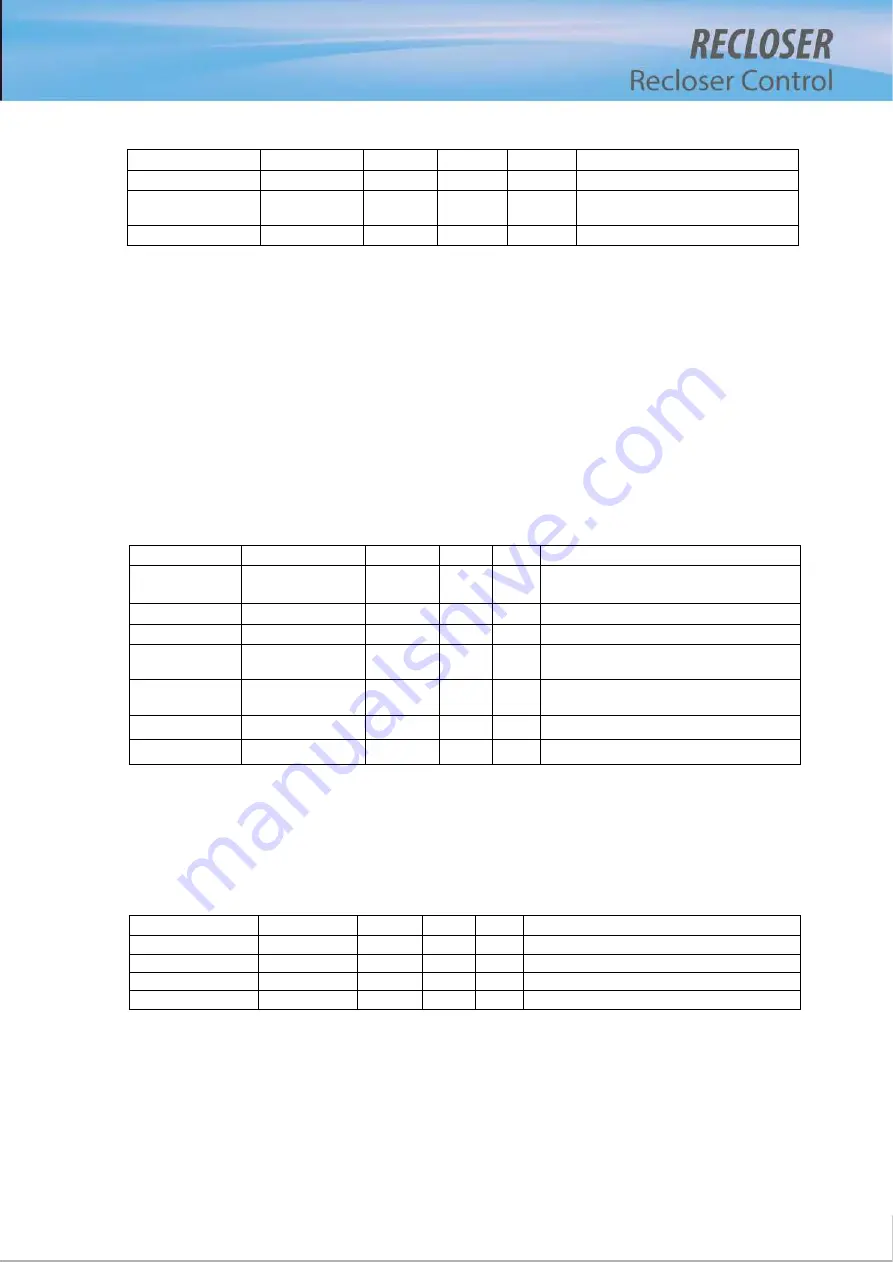

<Table 5-19> Misc. Config

Item

Range

Default

Step

Unit

Explanation

Door Open Contact

N.O(A)/N.C(B)

N.O(A)

Set contact type for door open(DI6)

AC POWER LED

AC Fail/AC

Normal

AC Fail

Set contact type for AC POWER(DI3)

Insulator Type

Mold/SF6-GAS

Mold

Set contact type for Gaslow(DI7)

5.4. Communication Menu

It is a menu to set communication port to connect with upper system.

On this menu there are communication port setting in connection with SCADA system,

modem control signal setting in connection with modem, DNP3.0, IEC60870-5-101,

IEC60870-5-104, TCP/IP protocol related setting.

5.4.1. SCADA Port

It is a menu to set communication port in connection with SCADA system.

<Table 5-19> SCADA Port

The way to set is identical with 5.3.1

5.4.2. Modem Control

It is a menu to set modem control signal to connect SCADA system and modem.

<Table 5-20> Modem Control

The way to set is identical with 5.3.1

5.4.3. DNP Config

It is a menu to set DNP3.0 communication related items.

Item

Range

Default

Step

Unit

Explanation

Baud Rate

1200~38400

9600

bps

Port connected with SCADA’s

communication speed setting

Parity

NO/EVEN/ODD

NO

Serial communication parity setting

Slave/DL Address

0~65534

2

1

DNP slave or IEC-101 D/L address setting

ASDU Comm

Addr

0~65534

2

1

ASDU common address setting

Select Protocol

DNP/DNP-TCP/IEC-

101/IEC-104/

DNP

DNP3.0 and DNP-TCP and IEC870-5-101

protocol and IEC870-5-104 protocol setting

Select Map

Full Map/User Map

Full Map

Protocol map type setting

Clear User Map

Delete saved user map in backup memory

Item

Range

Default

Step

Unit

Explanation

Comm Line

2 / 4

4

Modem communication line setting

RTS Off Delay

10~500

100

10

ms

After TX completion, delay setting for RTS Off

CTS Time out

0~255

3

1

s

After RTS enable, CTS waiting time setting

DCD Time out

0.1~30

10

0.1

s

TX waiting time when DCD is enable on 2 Line

Summary of Contents for RECLOSER

Page 1: ...User Manual Document Version 1 5 Feb 28 2019 http powersys kr http www powersys kr...

Page 14: ...8 3 5 Mechanical Performance and Size Weight 3 5 kg FRONT VIEW Figure 3 1 Front View...

Page 15: ...9 SIDE VIEW 343 00 310 00 91 00 Figure 3 2 Side View...

Page 16: ...10 TOP VIEW 84 0 260 0 225 0 1 0 0t Figure 3 3 Top View...

Page 17: ...11 REAR VIEW 180 0 120 0 Figure 3 4 Rear View...

Page 22: ...16 Controller PCB 215 00 103 90 121 10 112 50 112 50 235 00 205 00 Figure 3 8 Controller PCB...

Page 69: ...63...

Page 71: ...65 Example configuration file...

Page 73: ...67 2 TC Curve 1 4 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 1 2 3 4...

Page 74: ...68 3 TC Curve 5 8 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 5 6 7 8...

Page 77: ...71 6 TC Curve A D 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting A B C D...

Page 78: ...72 7 TC Curve E M 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting E K L M...

Page 79: ...73 8 TC Curve N T 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting N P R T...

Page 80: ...74 9 TC Curve V Z 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting V W Y Z...