5

ASSEMBLY

• Replace the upper and side belt guards and secure in

place with the belt guard locking knob.

• Plug the power cord into the correct receptacle.

(Refer to

Power Source

paragraph in this section of

the manual.)

• Turn the switch ON and OFF to make sure the belt

is tracking at high speed; readjust with tracking knob

if needed.

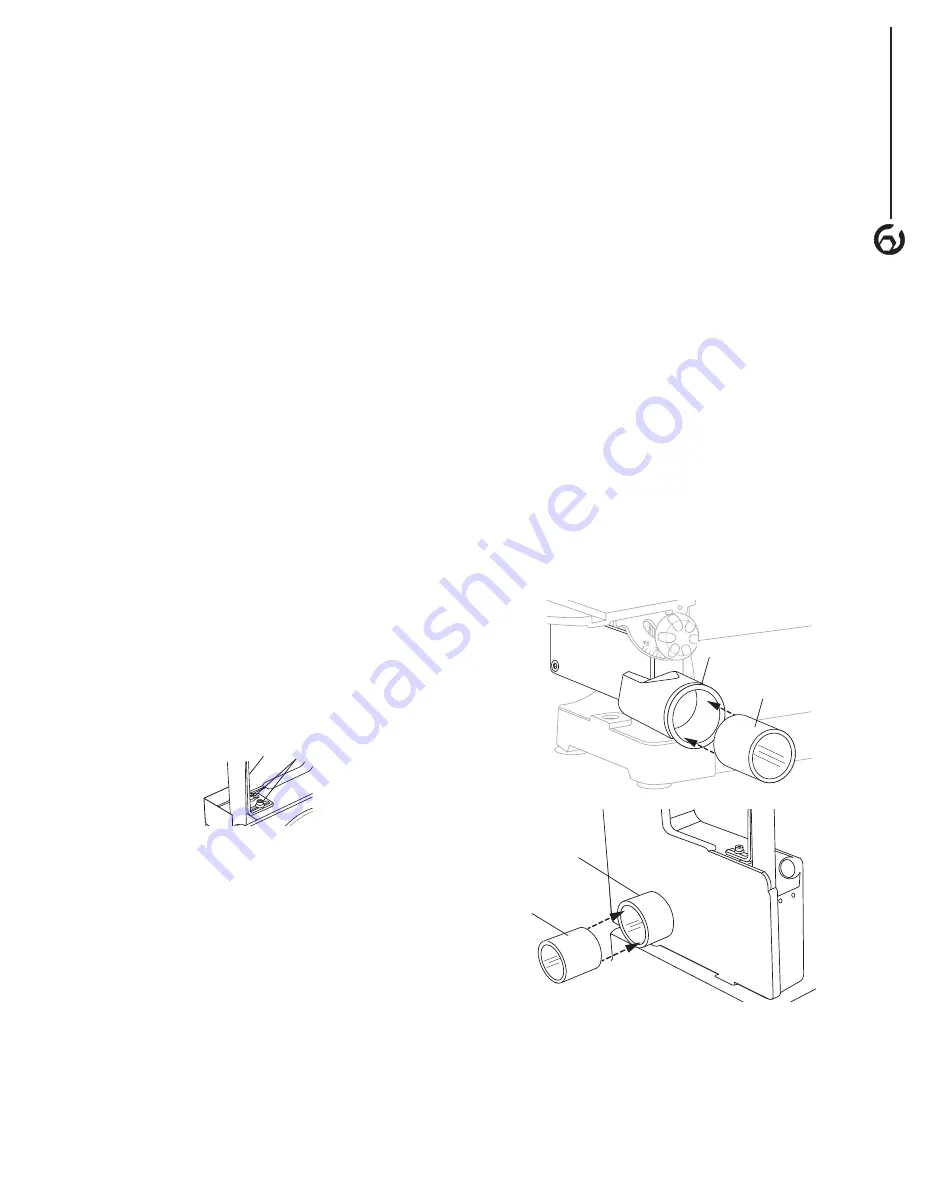

BACKSTOP

Refer to Figure 12

The backstop is a surface to sand against.

To Adjust

• Remove the sanding belt table. See

Mount the

Sanding Belt Table

paragraph and reverse the order

of assembly.

• Loosen the two screws on backstop and slide the

backstop in or out until it just touches the back of

the belt. Retighten the two screws and replace the

sanding belt table. See

Mount the Sanding Belt

Table

paragraph.

To Remove

The backstop can be removed for polishing and

contour sanding.

• Remove the sanding belt table. See

Mount the

Sanding Belt Table

paragraph and reverse the order

of assembly.

• Remove screws and washers securing backstop. Place

screws, washers and backstop in a safe place for future

use.

• Replace the sanding belt table. See

Mount the

Sanding Belt Table

paragraph.

Figure 12

Screws and

Washers

Backstop

REPLACING THE SANDING DISC

Refer to Figure 2, 3

NOTE:

This sander disc uses 5" self adhesive

sanding disc.

• Turn the machine "OFF", and disconnect the machine

from the power source before assembling the

sanding disc.

• Remove the sanding disc locking levers and slide the

sanding disc table from the sander. See Figure 3.

• Remove the screws and washers securing the dust

chute and remove the dust chute from the sander. See

Figure 2.

• Peel the old sanding disc from the sanding wheel. Clean

the sanding wheel with mineral spirits. Make sure the

surface is clean and dry.

• Position the new sanding disc onto the sanding disc and

press into place.

• Reassemble the sanding disc table and dust chute.

Adjust the sanding disc table, if needed. See to

Adjust

Sanding Disc Table.

DUST PORT OPTIONS

Refer to Figure 13

The dust ports can be easily connected to a dust

collection system with a large diameter shop

vacuum hose.

Sanding operations are inherently dusty. This sander is

equipped with two 1-3/4” OD x 1-1/2” ID dust ports to help

minimize the amount of dust escaping into the surrounding

air. Attach the dust collection system vacuum hose to the

dust chute.

NOTE:

The dust chute is shipped with an adapter for

use with smaller hose dust collectors. This adapter has a

1-1/4” ID and can be used in either dust port.

NOTE:

The use of a dust collection system is strongly

recommended when using the belt/disc sander. Use of a

mask or respirator is still recommended even when using

a dust collection system.

Figure 13

Dust Port

Adapter

Dust Port

Adapter

Dust Port

Dust Port