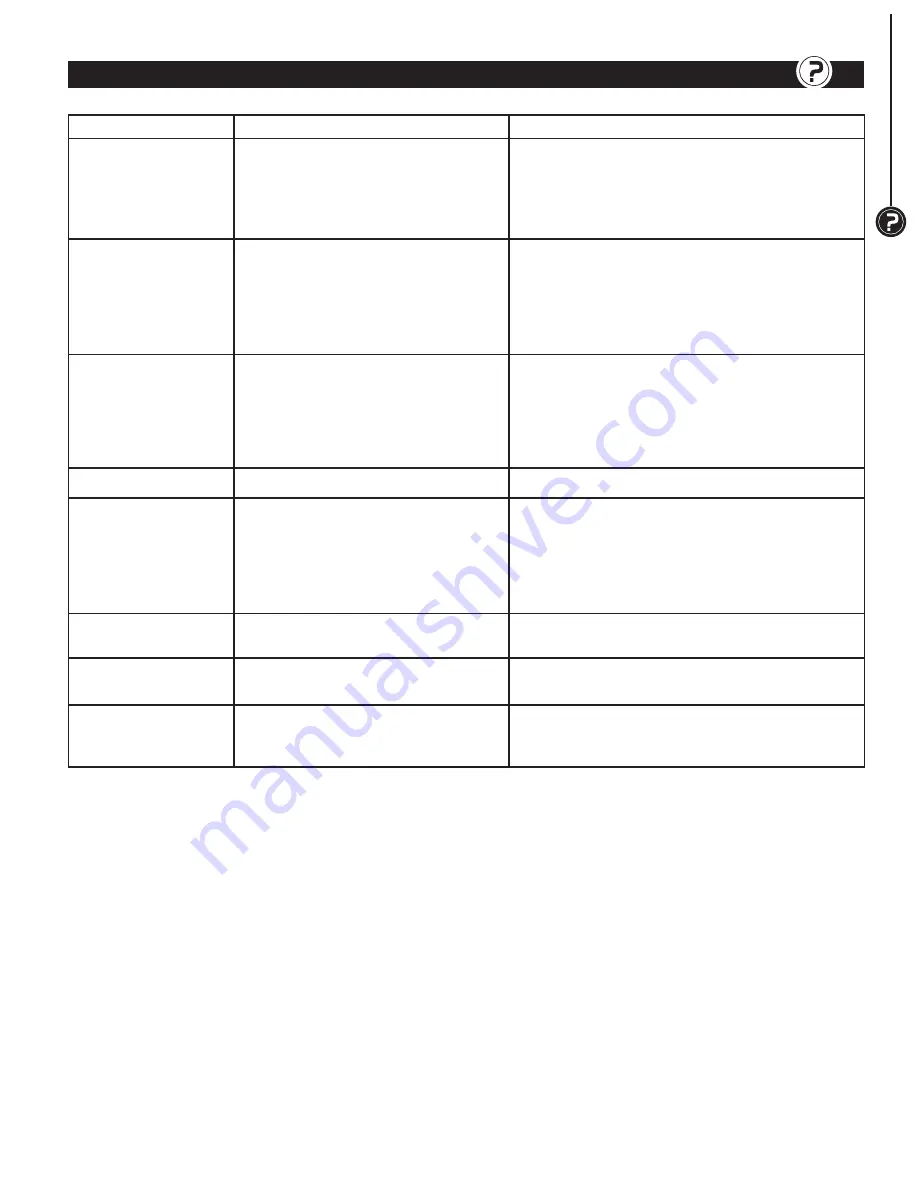

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Motor will not start

1. Low voltage

2. Open circuit in motor or loose

connections

3. Defective switch

4. Defective capacitor

1. Check power line for proper voltage

2. Inspect all lead connections on motor for loose

or open connection

3. Replace switch

4. Replace capacitor

Motor will not start;

fuses blown or circuit

breakers are tripped

1. Short circuit in line cord or plug

2. Short circuit in motor or loose

connections

3. Incorrect fuses or circuit breakers

in power line

1. Inspect line cord or plug for damaged insulation

and shorted wires

2. Inspect all lead connections on motor for loose

or shorted terminals or worn insulation on wires

3. Install correct fuses or circuit breakers

Motor fails to develop

full power (power

output of motor de-

creases rapidly with

decrease in voltage

at motor terminals)

1. Power line overloaded with lights,

appliances and other motors

2. Undersize wires or circuits too long

3. General overloading of power

company’s facilities

1. Reduce the load on the power line

2. Increase wire sizes, or reduce length of wiring

3. Request a voltage check from the power com-

pany

Motor overheats

Motor overloaded

Reduce load on motor

Motor stalls (result-

ing in blown fuses or

tripped circuit break-

ers)

1. Short circuit in motor or loose

connections

2. Low voltage

3. Incorrect fuses or circuit breakers

in power line

4. Motor overload

1. Inspect connections in motor for loose or

shorted terminals or worn insulation on lead wires

2. Correct the low line voltage conditions

3. Install correct fuses or circuit breakers

4. Reduce load on motor

Machine slows down

while operating

Applying too much pressure to work-

piece

Ease up on pressure

Abrasive belt runs off

top wheel

Not tracking properly

See operation “Adjusting Belt Tracking”

Dust collection not

working

1. Dust collection bag full

2. Belt loose or broken

3. Impeller loose or broken

1. Empty dust collection bag

2. Replace belt

3. Replace impeller

TROUBLESHOOTING

9

9

TROUBLESHOOTING

Summary of Contents for BD4800

Page 12: ...4 X 8 BELT DISC SANDER PARTS ILLUSTRATION 10 PARTS LIST 10 ...

Page 16: ......