Do not permit fingers to touch the terminals of plug when

installing or removing from outlet.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• The conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect

the green (or green and yellow) wire to a live terminal.

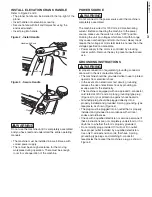

A temporary 3-prong to 2-prong grounding adapter (see

Figure 5) may be used to connect this plug to a matching

2-conductor receptacle as shown in figure 5. The tempo-

rary adapter should be used only until a properly grounded

outlet can be installed by a qualified electrician.

In Canada, the use of temporary adapter is not permitted

by the Canadian Electric Code. Where permitted, the rigid

green tab or terminal on the side of the adapter must be

securely connected to a permanent electrical ground such

as a properly grounded water pipe, a properly grounded

outlet box or a properly grounded wire system.

• Many cover plate screws, water pipes and outlet boxes

are not properly grounded. To ensure proper ground,

grounding means must be tested by a qualified

electrician.

EXTENSION CORDS

Use proper extension cords. Make sure the extension

cord is in good condition. Use only 3-wire extension cords

that have 3-prong grounding type plugs and 3-pole

receptacles which accept the tool plug. When using an

extension cord, make sure to use one heavy enough to

carry the current of the machine. An undersized cord will

cause a drop in the voltage, resulting in loss of power and

overheating. Use the table to determine the minimum wire

size (A.W.G.) extension cord.

Extension Cord Length

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.W.G.

Up to 25 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

25 to 50 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

NOTE:

Using extension cords over 50 ft. long is not

recommended.

ELECTRICAL CONNECTIONS

• Turn the switch off and disconnect the machine from

power source before performing any repair or

maintenance work.

• Some electrical wiring and connection work must be

performed by a qualified electrician in accordance with

local regulations.

• There is a green grounding wire fastened to the frame of

the machine to provide shock protection. Do not

disconnect the grounding wire from the frame.

• The motor is rated for used at 120 Volts.

• Connect this machine to 3-Conductor power outlet with

appropriate rating only.

• Use only 3-pronged extension power cord with

appropriate rating with this machine.

• When changing the power cord, use only 3-pronged

power cord with appropriate rating.

• The power switch is a single pole rocker switch with

locking mechanism. Remove the key when not in use

to prevent accidents.

WARNING

Figure 5 - 2-Prong Receptacle

Figure 4 - 3-Prong Receptacle

Grounded outlet Box

3 - Prong Plug

Grounding Prong

WARNING

Make Sure This

Is Connected

To A Known

Ground

2-Prong

Receptacle

Grounding Lug

Adapter

2-Prong Plug

4

ASSEMBLY

Summary of Contents for PL1252

Page 14: ...Figure 11 12 1 2 THICKNESS PLANER PARTS ILLUSTRATION 12 ...

Page 18: ......

Page 19: ......

Page 20: ...Southern Technologies LLC 3816 Hawthorn Court Waukegan IL 60087 ...