7

INSTRUCTIONS PL600/PL1000

5

0m

m

28

7m

m

91

m

m

50

m

m

3.3 Preparation for Motor Installation

PL600/PL1000 is not applicable to a gate which is inefficient or unsafe, neither to solve the defects due to incorrect

installation nor poor maintenance.

Check the following items before going for installation:

1). Make sure the weight and dimensions of the gate conform to the operation range of PL600/PL1000.

Don’t use

PL600/PL1000 if the gate specifications do not meet the requirements.

2). Make sure the gate structure conform to the criteria of automatic operation and force regulations.

3). Make sure there is no serious friction existing in the opening or closing travel of the gate.

4). Make sure the gate is at horizontal level that the gate will not move aside at any position.

5). Make sure the gate can bear the impact of the motor torque when it is installed on the plate which the surface is

sufficiently sturdy.

6). Make sure that the installation area is not easy to be invaded by flood. If necessary, mount the raised from the

ground.

7). Make sure the photo sensors (optional) are installed on flat surfaces to ensure the two ends of receiving and

transmitting corresponded to each other.

8). Make sure the installation area is suitable to the size of and the area is safe and easy to release the gearmotor.

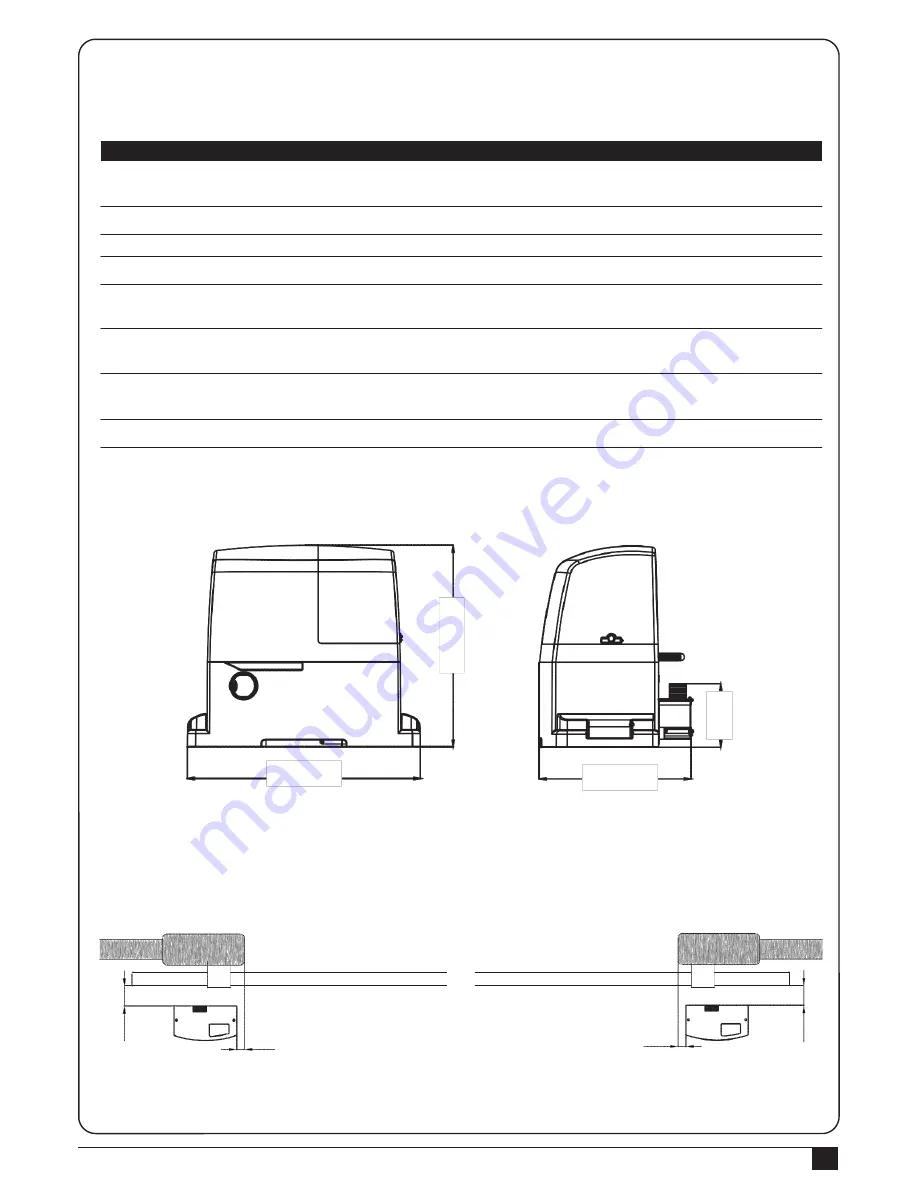

Check the dimensions of the motors as below:

Figure 11

332mm

216mm

9). The installed at the left side and at the right site as below:

Gate without rack: the distances indicated in

Figure 12.

Figure 12

SX

DX

50mm

50mm