INSTRUCTIONS PL600H/PL1000H

11

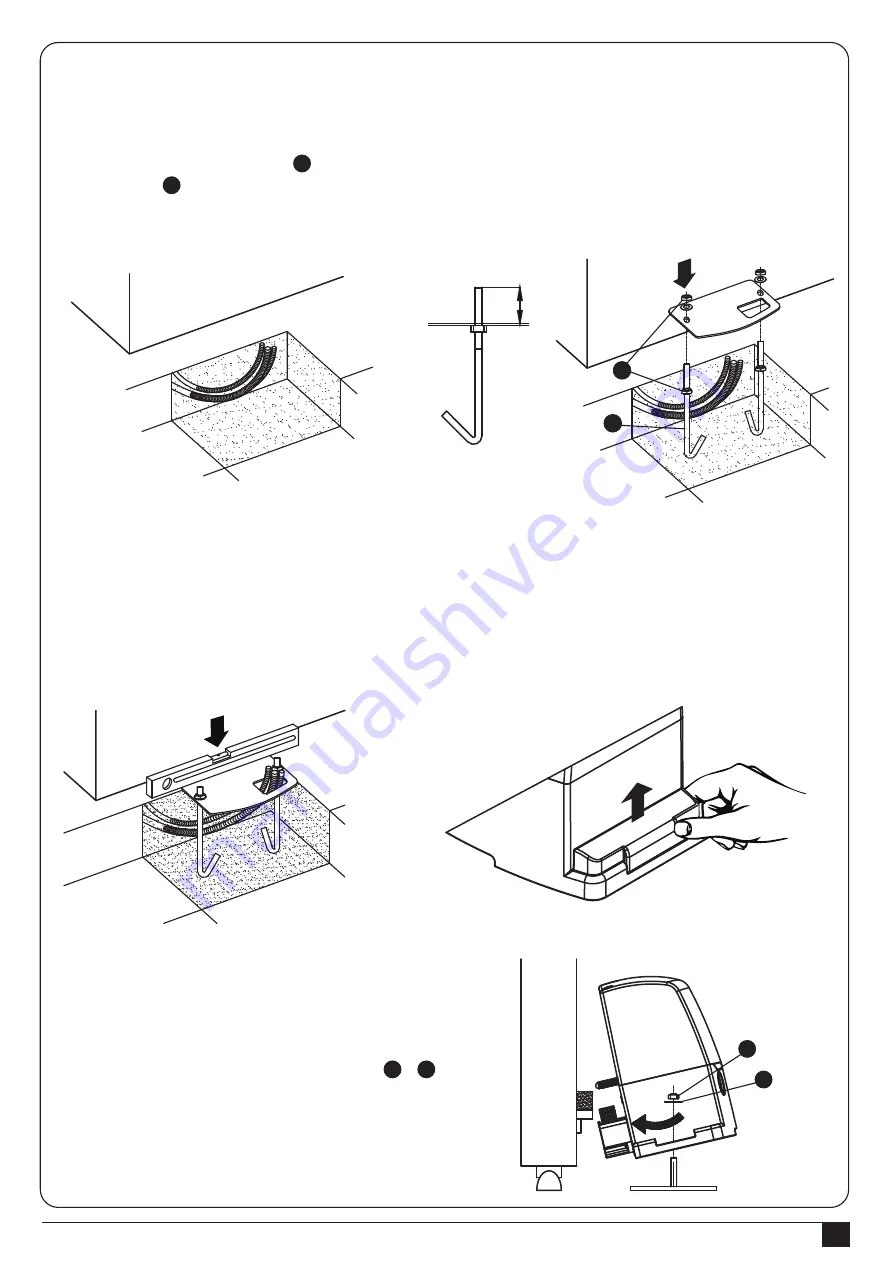

10). Put the gearmotor onto the plate and underneath

the rack. This step of installation can be operated

by tilting the gearmotor so that the pinion can be

easily under the rack. Make sure the gearmotor

lies ideally parallel with the gate. Then fix it by

fastening the two nuts and washers. (as the &

parts in

Figure 28

)

11). If necessary, adjust the height of the gearmotor

(Max. 10mm) with the 4 dowels. It is better to fix

the gearmotor without dowels as it is fastened

firmly and securely on the plate.

1). Dig the foundations based on “Preparation for Motor Installation” and please notice the distances indicated in

Figure 12

.

2). Lay the conduits for the power cables and leave 30-50 cm longer as

Figure 24

.

3). Fit the two bent bins (as below part in

Figure 25

) into the foundation and fix them above and below with two

nuts (as the part in

Figure 25

); make sure the outstanding part does not exceed the maximum height 25~35 mm

as

Figure 25

.

B

C

D

A

Figure 24

Figure 26

Figure 27

Figure 28

Figure 25

3.3.1.2 Installing on Gates with Rack

4). Put the foundation plate and make sure the gate keeping the distances shown as

Figure 12

.

5). Fit the conduits through the hole of the foundation plate.

6). Pour the concrete.

7). Sink the plate into the concrete and make sure it is parallel to the leaf as below

Figure 26

.

8). After the concrete is dry enough, remove the two upper nuts (which will no longer be used) form the plate and cut

the cable conduits above the plate if the conduits are too long.

9). Open the cap by the rear of the gearmotor as shown in

Figure 27

.

A

B

25~35mm

C

D

Summary of Contents for PL1000H

Page 1: ...FOR RESIDENTIAL USER MANUAL SLIDING GATE OPENERS PL600H PL1000H 24V DC MOTOR ...

Page 2: ......

Page 27: ......