2

3

Function

Pulling through the unloaded chain

Make sure the chain is unloaded and set the selector to neutral position (N). Pull the chain through by hand to the desired position.

Warning!

If the selector is in position UP or DOWN when the chain is pulled, the lever may rotate like a propeller, which could be

dangerous.

Warning!

If the lever hoist is used on a load which is too light, the brake function will not engage. The load must be at least 3% of

maximum load. For example a minimum load of 30 kg is necessary to engage the brake on a 1 tonne hoist. For lightloads choose a

smaller

lever

hoist.

If it proves impossible to pull the chain through despite the selector being in neutral, it may be necessary to release the brake first, by turning the

brake wheel anti-clockwise. If this does not help, set the selector to position DOWN, load the chain slightly and jerk the lever in clockwise direc-

tion. Then try again without load but with the selector in neutral.

Suspension of lever hoist

Make sure the hoist in suspended from an eye,

shackle or similar with sufficient bearing

capacity. With the chain tightened, both hooks

must be in line (Fig. 3a).

NB!

Neither hoist, hooks nor chain

may be subjected to bending stresses

(Figs. 3b and c and Fig. 4).

Attachment of loads

Check the equipment well before use. Improper attachment of loads can be highly dangerous (see Figs. 4 a–e).

Only use straps and slings of sufficient load capacity. Make sure the load is not anchored to the floor/ground or is otherwise fixed before

making the lift.

Lifting/pulling

With the selector in position UP, operate the lever to tighten the chain. Check for safety before lifting the load to the desired position. If the load is

too light to be lifted, hold onto the brake wheel so you hear the snapping sound. You will then be able to lift the load with just one hand. If the lever

is released while lifting, the load will be held in its current position by the reaction brake. The lever hoist can also be used for pulling and fixing

loads.

Further safety precautions

•

Never lengthen the lifting lever with a pipe or similar. Use only hand power on the lever. If the load seams too heavy, use a bigger lever hoist

or reduce the load.

•

Make sure no-one stands beneath a hanging load.

•

Do not raise or lower so far that the load hook or the stop eye hits the block housing.

•

Do not set the selector to neutral under load.

•

The block must not be subjected to dynamic stresses, for example where a load connected to the block is launched from a height.

•

Do not leave a block with a suspended load unattended.

Lowering

With the selector in DOWN position, operate the lever to lower the load. Wait until the chain has been completely freed of load before moving the

selector to Neutral (N) to rapidly pull out the chain. (See “Pulling through the unloaded chain”).

Warning:

Do not overload the brake by prolonged lowering. It may cause brake function to fail.

Multiple lifting

Multiple lifting presents special risks. This is when two or perhaps more hoists are used simultaneously for the same load. Danger to persons and

material damage can arise due to dynamic stresses and uneven load distribution causing individual hoists to become overloaded. A competent

person with experience in multiple lifting must therefore supervise this type of lifting tasks.

The total weight of the target object and its load distribution must be known or calculated.

For a variety of reasons, the centre of gravity can be difficult to determine, and thus so will the distribution of the load each hoist must bear. In

cases where heavy, bulky loads must be handled and it is not possible to estimate all factors correctly, the max working load limit (WLL) of each

hoist must be reduced by at least 25%.

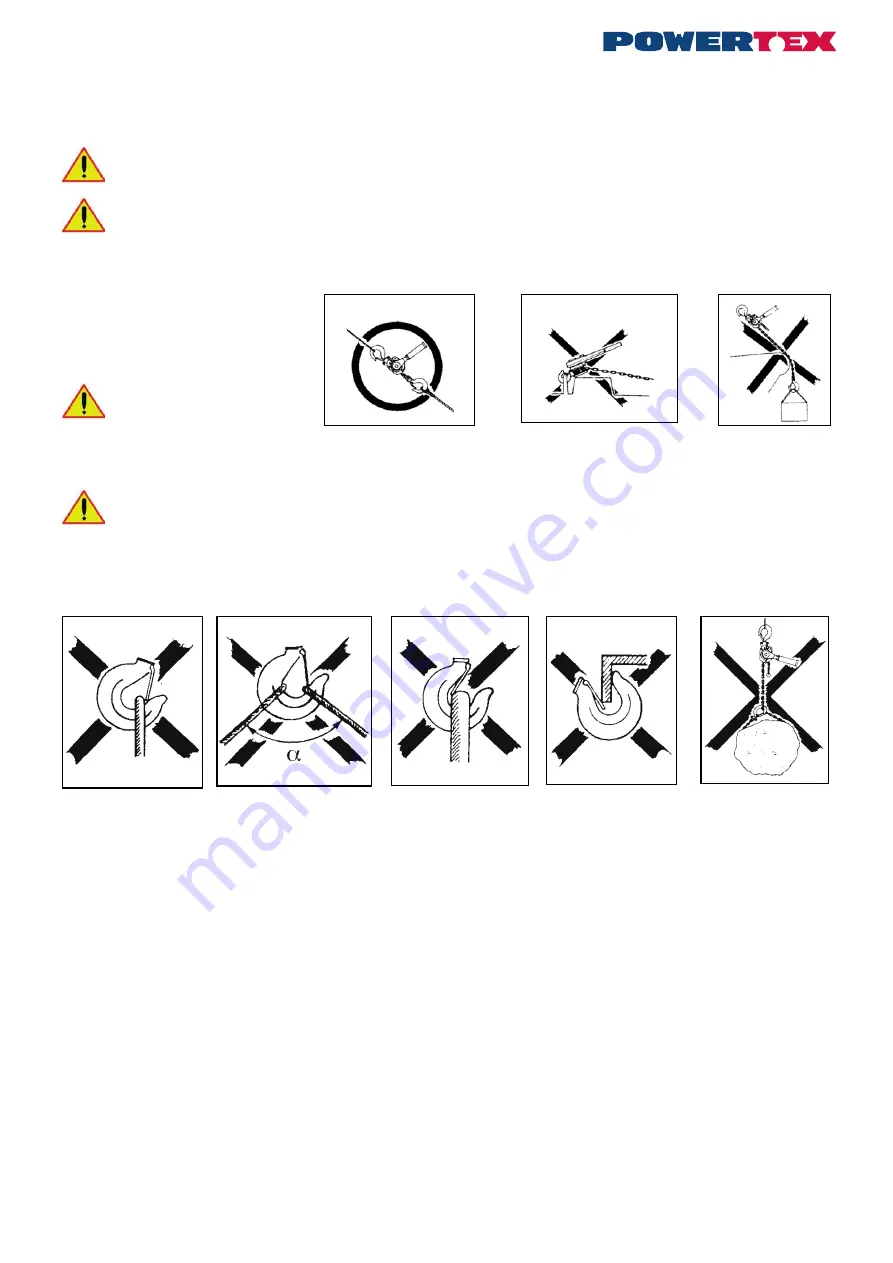

Fig 3 a Fig 3 b

Fig 3 c

Fig 4 a

The sling is applying

load to the hook tip!

Fig 4 b

Excessive top

angle on sling!

α max. 60°

Fig 4 c

Hook latch obstructed!

Fig 4 d

Hook tip subject to

additional bending stress!

Fig 4 e

Load chain must not

be used as a sling!

Summary of Contents for PALH-S1 Series

Page 12: ...12 ...