7 - 1

3x3 UPS Troubleshooting

Issue 2 - November 2001

Chapter 7 - Troubleshooting

7.1 - Introduction

The UPS contain complex electronic control circuits which require a firm understanding,

in order to carry out comprehensive fault diagnosis and repair of the equipment. The aim of the informaĆ

tion contained in this chapter is to provide sufficient guidance to the trained service engineer, to enable

successful fault location to printed circuit board level. Once a faulty circuit board or component has been

identified, it should be replaced or returned to the nearest service centre for repair.

The troubleshooting information has been divided into the following main areas:

a)

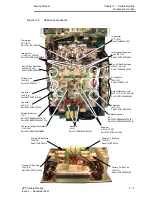

Component location and identification.

b)

Diagnostic information.

c)

Troubleshooting procedures.

d)

Test procedures.

Note: When following the procedures cross referencing is inevitable, therefore

it is recommended that this chapter is read in its' entirety, before

commencing work on the equipment.

There is no practical way of detecting an impending UPS malfunction, as most problems do not emerge

as a gradual performance degradation. Generally the UPS will either work correctly or shut down with

or without a warning indication.

In the event of a UPS malfunction troubleshooting should be carried out methodically along the following

guide lines.

7.1.1 - General Fault Identification Procedure

When first summoned to a UPS fault the immediate action should be to observe and record the LED

indication displayed on the unit operator panel.

1.

Determine the UPS power Status.

2.

Note the control switch configuration, and also the warning horn sequence if it is operating.

WARNING

During troubleshooting it will be necessary to power up the unit with the side or top covers

removed, in this situation exposure to potentially lethal voltages is possible even with the

input utility supply switched off.

Take great care at all Swiss to minimise the risk of contact with live voltages, especially when

working around the battery or the DC bus.

3.

Power down the unit, and ensure that the DC Bus Safety discharge check is carried out.

4.

Gain access to the internal components follow the procedure for removing the UPS covers.

5.

Check the serviceability of the UPS Fuses refer to the check list on page 7Ć12.

6.

Apply power and analyse PCB LED indications.

7.

Refer to the common fault identification chart on page 7Ć9 to identify possible fault

conditions.

8.

Check DC converter power components. Refer to the procedures on page 7Ć19.

9.

Check Inverter power components. Refer to the procedure on page 7Ć19.

Note: When checking signal levels refer to the table of typical normal values on

page 7Ć11 for comparison.