31

for «N» units in parallel, as well as the features of the own

«Backfeed protection».

•

In parallel systems, the length and cross section of the wires

that goes from the panel board to the each UPS and vice

versa, will have the same for all of them, without any exception.

• Always take into account the cross cable section, as regards to

the size of the own terminals of the switches, in order to

embrace all their section properly for an optimal contact

between both elements.

• In the nameplate of the equipment, nominal currents are only printed

as it states the EN-IEC 62040-1 safety standard. The input current

calculation, has been done taking into account the power factor and

the own efficiency of the equipment.

• If other peripheral elements are added to the UPS or parallel system

input, output or bypass like transformers or autotransformers, take

into account the currents stated in the own nameplates of those

elements in order to use the suitable cross sections, always

respecting the Local and/or National Low Voltage Electrotechnical

Regulations.

• When a UPS or parallel system include a galvanic isolation

transformer, as standard, option or installed by yourself, either at

the input line, bypass line, output or in all of them, protections

against indirect contact (RCD) have to be fitted in at the output of

each transformer, because in case of electrical shock in the

secondary winding (output of the isolation transformer), its

isolating feature will block the tripping of the protections

located in the primary winding.

• As a reminder, all isolation transformer installed or supplied from

factory, has the output neutral connected to earth by means of a

bridge that connects the neutral and earth terminals. In case, an

isolated neutral were required, remove this bridge, by taking the

precautionary measures stated in the respective local and/or

national low voltage regulations.

• To enter the cables inside the cabinet, there are either cable glands

(PR)

assembled in the metallic structure or an only one opening as

a register mode.

• Models with power rate higher than 40 kVA (LV) / 80 kVA (HV),

have a rod to fix the connection wires of the equipment to it, by

means of clamps

(BF)

.

Once the cables are connected to their respective terminals,

proceed to fix them by means of clamps to the rod

(BF)

.

5.1.4.5. Preliminary considerations before connecting,

as regards to batteries and protections.

• Battery protection has to be always done by fuses as minimum.

So, the physical layout of them is determined by the tangible

location of the batteries.

Standard equipments up to 20 kVA (LV) / 40 kVA (HV), batteries

are supplied already fitted in the same cabinet of the

equipment and B1 models and/or higher power rate are

supplied in a separate cabinet. Therefore, battery protection is

arranged as follows:

In the UPS (stated in this document as

(Q3)

):

Battery fuse holder switch with 3 fuses in models up to 20

kVA (LV) / 40 kVA (HV) or switch for B1 versions and higher

power rates.

In the battery cabinet and standard back up time:

Battery fuse holder switch with 3 fuses in models up to

60 kVA (LV) / 120 kVA (HV). Stated in this user's manual

as

(Q8)

.

Switch for battery string no 1 in models higher than 60 kVA

(LV) / 120 kVA (HV). Stated in this user's manual as

(Q8)

.

Inside there are 3 non-switchable fuses.

• In relation to fuses, they will be supplied inside of a plastic bag

together with the equipment documentation or inside the

battery cabinet, less those battery modules of models higher

than 60 kVA (LV) / 120 kVA (HV), which are mechanically fixed to

the cabinet.

• The original type of the battery circuit, preset from factory is

opened.

– +

Put the fuses

in the corresponding fuse holder switch and

turn

it «On»

when it is indicated only

, never before. To

operate in other way, can cause

irreversible damages to the

equipment or serious and/or very serious injuries

to the

fitter, as he has been exposed to a possible

electrical

discharge

during the connection of the UPS with the battery

set or battery cabinet.

•

Do not manoeuvre the battery fuse holder and/or

switch

when the equipment is turned on. This mechanisms

cannot be turned on/off with load

.

•

When power supply to the equipment or parallel system is

broken beyond of a simple intervention and it is planned to

have them out of service for long time, proceed to shut them

down completely and remove the 3 fuses from the fuse holder

switch or battery module for higher safety, and keep them in a

safe place. For models higher than 60 kVA (LV) / 120 kVA (HV),

open the battery switch in both cabinets (equipment and battery

module).

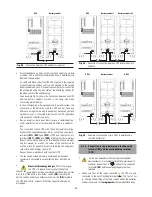

5.1.4.6. Access to inside the cabinet for its connection.

• Any equipment and battery cabinet from this

series has

terminals as connection elements for the power. Also UPSs have

a terminal strip for the auxiliary connections and HDB9 / DB9

communication connectors.

To have access to them proceed as follows and repeat the same

procedure in each unit for parallel systems:

Unblock the lock/s

(CL)

by means of the key

(LL)

supplied

with the equipment, turn it to clockwise 45º.

Open the front door

(PF)

completely. DB9 connectors of

communication ports and terminals for EPO remote button

are visible.

Remove the screws

(t1)

that fix the terminal cover

(TB)

to

the cabinet and remove it; connection terminals are visible.

When finishing the UPS connection, put the cover

(TB)

back, fix it with the screws

(t1)

, close the door

(PF)

with

the key

(LL)

and lock

(CL)

.

Take into account the cross cable section, as regards to the

size of the own terminals of the switches, in order to embrace

all their section properly for an optimal contact between both

elements.