P

OWERWINCH

24'

C

LASS

R

OPE

A

NCHOR

W

INCH

5

W

IRING THE

U

NIT

WARNING

A

LWAYS

disconnect the battery before working on

electrical equipment.

WARNING

A

LWAYS

use the recommended wire size and rated circuit

breakers. Failure to use the furnished and recommended sizes can cause a fire

hazard and void warranty.

NOTICE

When routing the wiring, avoid sources of heat.

NOTICE

When routing the wiring, avoid sharp edges that can cut or fray

the wire insulation.

1. Determine the switch location.

Ensure that there is adequate room

behind the mounting surface for the

switch and wiring.

2. Drill a 1/2" hole through the

mounting surface.

3. Center the label over the hole,

remove the release paper and

attach.

4.

Route one R

ED

and one B

LACK

12 awg wire from the anchor to the switch

location. Be sure to allow adequate wiring to make connections, allow the

wire to have some slack when routing. Secure the wires with wire ties.

5.

At the winch, attach the new wires to the motor wires using the butt connectors.

Ensure that the crimps are solid and that the wires cannot come loose

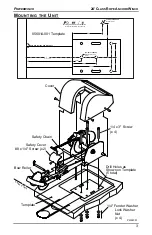

Anchor

Winch

Control

Switch

(D)

(C)

(B)

(A)

15A Circuit Breaker

Battery

Black

12awg

Red

12awg

Black

12awg

Red

12awg

PW24003

6. At the switch position, terminate wire with a 12awg 1/4" female disconnect.

Ensure that the crimp is solid and cannot pull off.

7. Connect the wires to the switch. The R

ED

wire goes to terminal "B" and the

B

LACK

wire goes to terminal "A".

8. Route one R

ED

and one B

LACK

12 awg wire from the switch to the battery

location. Be sure to allow adequate wiring to make connections, allow the

wire to have some slack when routing. Secure the wires with wire ties.

9. At the switch position, terminate wire with a 12awg 1/4" female disconnect.

Ensure that the crimp is solid and cannot pull off.

10. Connect the wires to the switch. The R

ED

wire goes to terminal "C" and the

B

LACK

wire goes to terminal "D".

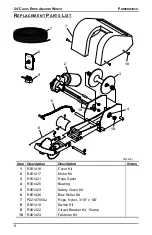

ANCHOR WINCH

CONTROL SW

ITCH

DOWN

POWERWINCH

Switch

Switch

Boot

PW24002a

1/2" Hole

Switch Label