24'

C

LASS

R

OPE

A

NCHOR

W

INCH

P

OWERWINCH

6

11. Push the switch through the switch mounting hole. Secure the switch with the

switch boot.

12. At the battery, terminate the B

LACK

wire with a 5/16 ring terminal. Connect

wire to the negative post of the battery.

13. Terminate the R

ED

wire with a #10 ring terminal. Attach the wire to the 15A

circuit breaker on the post opposite the buss bar.

14. Attach the circuit breaker to the positive (+) post of the battery.

T

ESTING THE

U

NIT

1. Ensure that all connections are secure and correct.

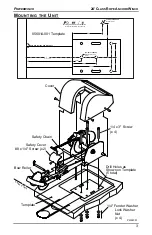

2. Without rope, press and hold switch in upward position. If wiring to switch terminals

is correct, the spool will spin counterclockwise (toward the rear of the winch).

If the motor runs in the wrong direction, switch is incorrectly wired. To

correct, switch the anchor red and black wires on back of the switch.

L

OADING THE

R

OPE

1. Feed rope through davit or bow roller and pull toward

anchor winch. Make sure rope is not twisted or kinked

and can freely run through bow roller or davit.

2. Insert the rope through the hole located in the side of the

drum (from the side opposite of the countersunk hole).

3. Feed enough rope through to tie an overhand knot at the

end of the rope.

4.

Pull the rope back until the knot is seated in the

countersunk opening.

5.

Keep tension on the rope and feed the rope on the drum

by running the anchor winch with the switch in the up

position.

Correct rotation is essential for proper

operation. The rope must feed from the top of the drum.

6.

Install the cover onto the winch.

A

TTACHING THE

A

NCHOR

Use a river, mushroom or navy type anchor up to a maximum weight of 40 lbs.

NOTICE

Do not exceed the 40lb maximum weight rating of the winch.

The winch will not operate correctly if the anchor is too heavy.

1.

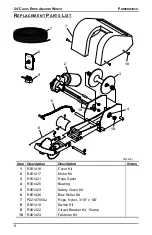

Tie an appropriate sized

anchor

shackle

(not

included) to the end of the

rope. Test that the knot will

not slip or come apart.

2.

Attach the shackle to the

anchor.

Anchor

Shackle

Rope Knotted

on Shackle

Anchor

PW24005

PW24004

Over Hand

Knot