tion without squeegee and vacuum then return to area after a min-

imum of 5 minutes and remove the suspended dirt, finish and

solution.

Squeegee:

Every week, check the blades of the squeegee and

wash them carefully. Then replace them in the correct working

position. If drying is not perfect even after the unit has been

cleaned, replace any blades which are excessively worn. If the

squeegee does not pick up enough water or streaks, lift and wipe

off the blades.

The pad driver or brush must be in good working condition

because it is the component which removes the dirt.

To remove the drive block, pad or brush:

• Fold the vinyl bumper over the left side of the

brush housing.

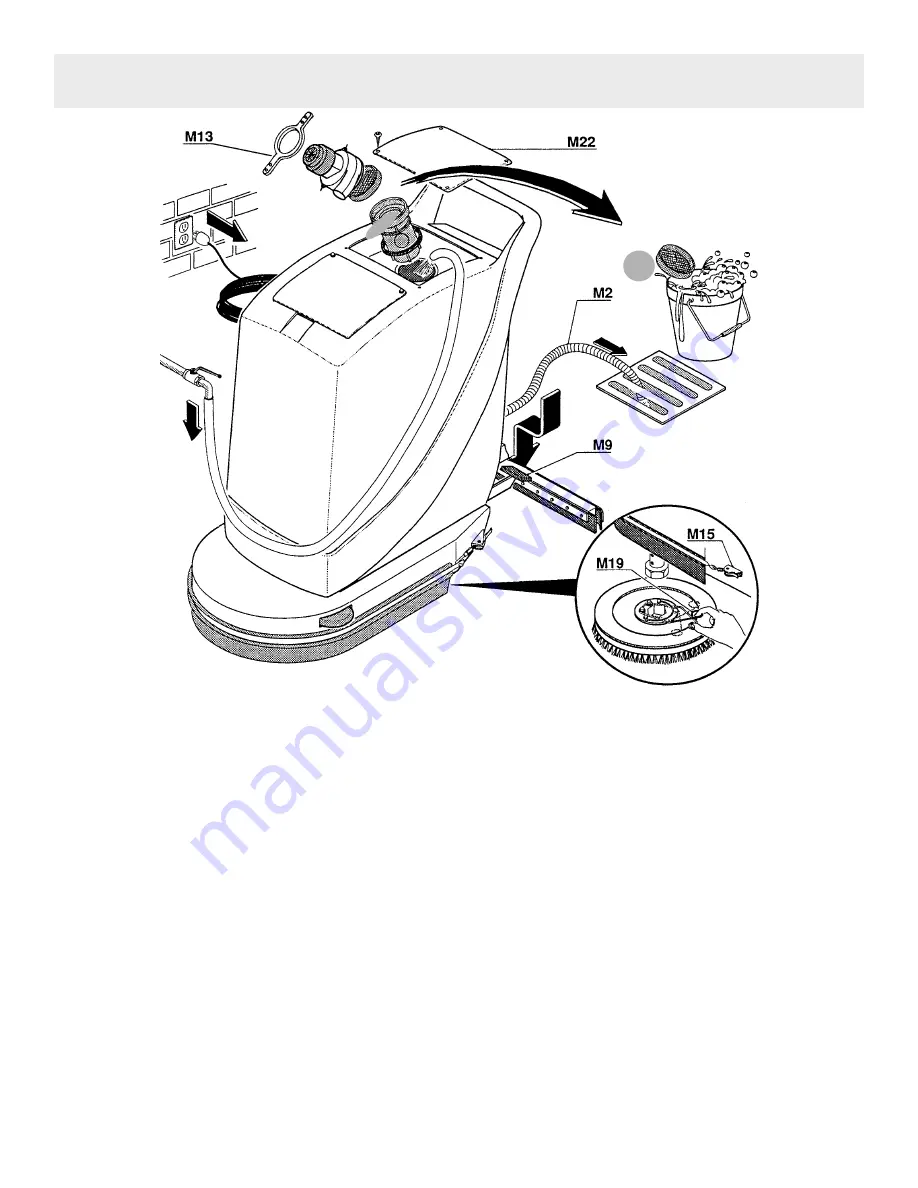

• Depress the brush pedal (M9) with your right hand

hold the brush position to allow free spinning by hand

of the driver or brush until the scissors style spring

lock can be squeezed with your left hand.

• Depress the brush pedal (M9) completely down

clearing the brush or drive block and slide brush or

driver out from under the housing.

To replace the drive block, pad or brush:

• Hold the brush pedal (M9) down while centering

the brush or driver under coupling. While squeezing the

spring lock together lower the coupling into the driver or

brush center by allowing the brush pedal to raise.

Release the scissors spring lock

The machine is supplied with a pad driver. Brushes in tynex,

poly and steel are available on request, together with floor pads

recommended for use with the pad driver.

Black

for stripping,

green

for deep scrub,

blue

for cleansing and red for light scrub.

Water collection tank:

This tank should be cleaned every week.

Lift the lid and remove the panel or funnel

M1

of the solution

tank. Remove the strap

M13

and lift the vacuum motor out of its

seat. Thoroughly clean the filter and wash out the dirt deposited

in the tank with a jet of water, allowing it to drain out through hose

M2.

If necessary, replace filter. Replace float cage with open side

facing front of scrubber.

- 7 -

GENERAL OPERATION