- 6 -

connect to the mains supply, make sure that the supply voltage is

the same as indicated on the battery charger itself. To charge the

batteries connect the connector

M5

, which comes directly from

the battery compartment, to the battery charger connector. The

charger will automatically regulate the charging cur-rent and will

turn itself off when the batteries are recharged.

WARNING:

The battery acid may give off harmful fumes. When

working near the batteries use protective glasses and clothes.

DO NOT PLACE ANY METAL TOOLS OF ANY KIND ON THE

BATTERIES.

Recharging the batteries generates explosive gas. Do

not smoke, light flames or make sparks. Make sure the charger

is switched off before disconnecting. Recharge the batteries in a

well-ventilated area and keep the cover open.

WARNING:

objects lying on the floor can be thrown at high speed

by the brushes, endangering people and/or property.

The area to be cleaned: In order to increase the effectiveness of the

detergent, the area to be cleaned should first be swept (manually

or by machine) to remove loose dirt, which may quickly clog up

the suction circuit.

Powering up and operation:

• Turn off the battery charger and disconnect it from the

machine. Connect battery cable to machine.

• Turn the key switch,

M6,

to position 1 and press buttons

M7

and

M8

;

• Lower the brush by pressing pedal

M9

;

• Lower the floor wiper by pressing pedal

M3

;

• Regulate the flow of detergent to a minimum using knob

M12

;

• Press lever

M10

, the machine will go forward, keep press the

button

M5

, the machine will go back-ward. Releasing

M10

to stop the machine

• Regulate the forward speed with potentiometer

M11

;

• Finally, use lever

M12

to regulate the dosage of detergent

according to the amount of dirt and the speed of the machine.

Particularly dirty floors: Certain floors or environments require

particular attention or even a second pass with the cleaner.

In this case you should make on pass with the wiper raised and the

brush in the working position; in this way the detergent remains on

the floor for longer and will dissolve the tougher dirt. The second

pass should be made with the brush and wiper lowered and at a

slower speed.

WARNING

this machine is designed to work in closed industrial environ-

ments on level floors or on inclines no steeper than 2%. Do not

use flammable chemicals and/or explosives with this machine.

Squeegee assembly:

Inspect and clean the floor squeegee

weekly and make sure to restore it to its working condition. If

the drying action is not perfect after cleaning the wiper

assembly, remove and replace any worn rubber blades.

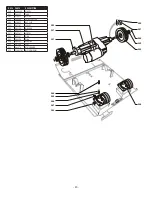

Brush:

The brush must be kept in working order; to remove a

worn brush proceed as follows (follow the procedure in

reverse to reassemble):

• Turn off the machine (key switch in OFF position) and lift the

brush with the pedal provided (

M9

);

• Release the catch

M15

and remove the rubber spray guard;

• Turn the brush to be re-moved by hand until the coils of spring

M19

are accessible;

• By closing together the coils of spring

M19

with your fingers

(as if you where closing a pair of scissors) the brush will

free itself;

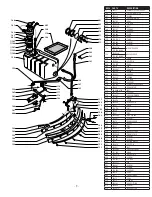

Recovery Tank:

clean the tank every week as follows: lift the

cover;

remove the cover of the suction motor

M1

; remove the motor

stop ring

M13

and remove the suction motor from its seat;

carefully clean the filter, net and sponge, and remove the dirt

which has accumulated in the tank.

Batteries:

Check the electrolyte level and top up with distilled

water if drops below the level of the battery elements. Keep the

batteries clean and dry with anti-static cloths. Recharging must

be carried out with the cell plugs removed and the cover of the

machine opened so as to allow the gases generated to escape.

In confined spaces these gases can be explosive, so recharging

should be done in a well ventilated area.

Summary of Contents for PAS20DX

Page 12: ......

Page 15: ......

Page 16: ...A Tacony Company 3101 Wichita Court Ft Worth TX 76140 1755...