- 7 -

Floor Wiper

Inspect and clean the floor wiper weekly. The wiper assembly

should be thoroughly cleaned to provide effective drying. If the

drying action is not perfect, remove and replace any worn rubber

b l a d e s .

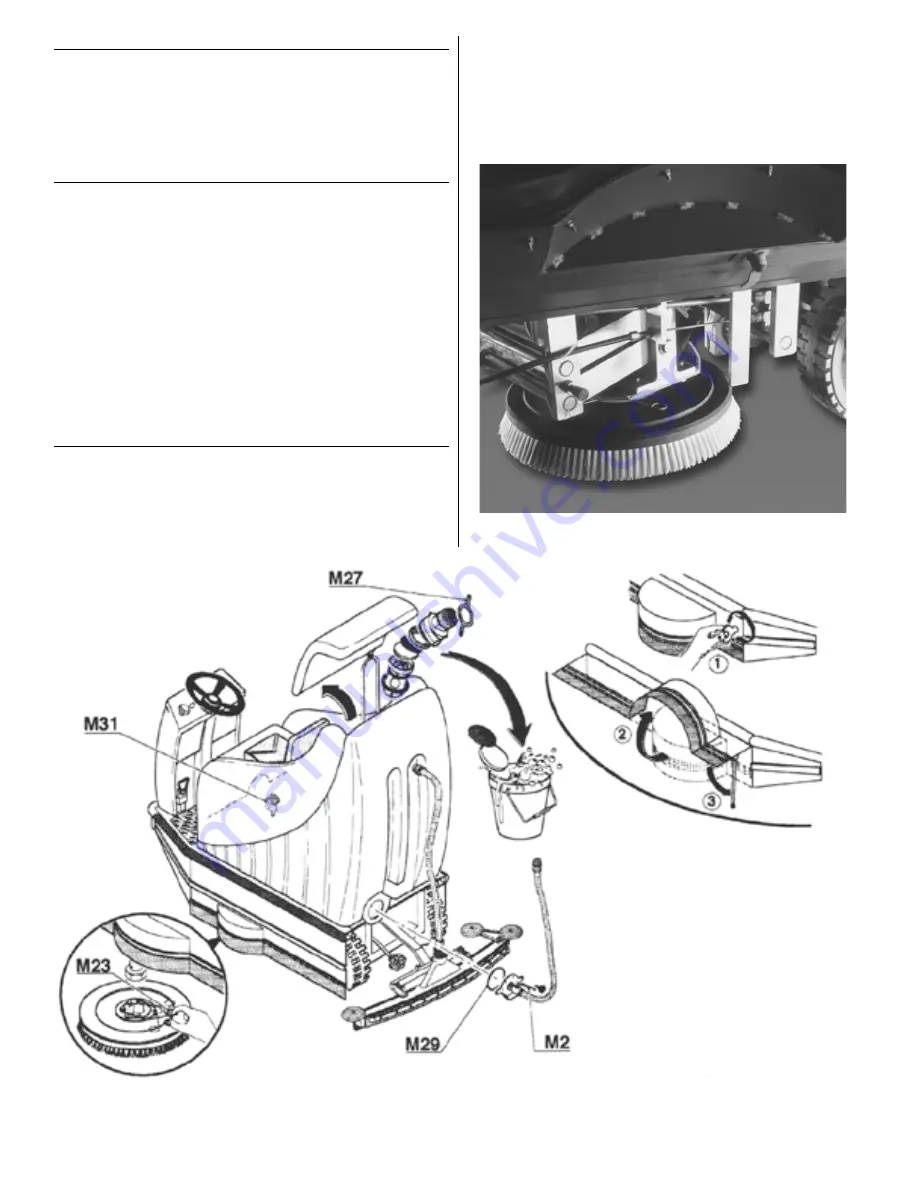

B r u s h

For maximum cleaning results, the brush should be replaced

when worn. To remove a worn brush lift the brushes with the reg-

ulator (M12) and switch off the machine. Disconnect the battery

c o n n e c t o r. Remove the key (M7) from the control panel. Using

the skirt lock key, unlock the panel, lift the skirt and prop it up

on the support rod (M30) provided. Turn the brush to be

removed by hand until the coils of spring (M23) are accessible.

By closing together the coils of spring (M23) with your fingers

(as if you were closing a pair of scissors) the brush will free

itself. Replace the brush.

B a t t e r i e s

Check the electrolyte level on a weekly basis. If the water drops

below the level of the battery elements, refill it with distilled water.

Keep the batteries clean and dry with anti-static cloths.

Recharging must be done with the cell plugs removed and the

cover of the machine open. The recharging process generates

gasses, which can be explosive in confined spaces. Only recharge

in a well-ventilated area.