5

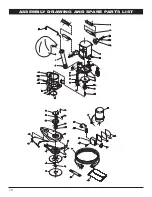

Fig. 8

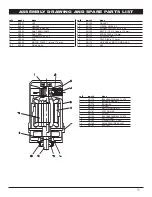

Fig. 9

5

Fasten the nut with the wrench included in the wrench

kit (Fig. 8).

Sanding angle adjustment

The sanding angle is set up at the factory for sanding with a

1/3 disk.

If you wish to change this angle, unloosen the nut securing

the wheel shaft. Then move the wheels up and down to

change the working angle as follows:

Wheels down: the machine sands point first

Wheels up: the machine sands flat. (Fig. 9).

Connection to power supply

The sander must be connected to a 115V/60 Hz power

supply with grounded plugs.

CAUTION!

To prevent electrocution keep the machine in a dry place. Do

not expose the machine to rain.

Use 3 wire of 14 AWG section cable.

The machine cord, extension cords and connection plugs

must be in perfect condition.

1

Before connecting the cord to the power supply make

sure that the switch is in the “0” position.

2

Place the machine in a vertical position and tilted

backward.

3

Hold the machine with your left hand.

4

Push the switch down with your right hand.

5

Press the disk on the floor and start sanding.

6

Do not press on the sander. Its own weight and the high

speed of the disk are sufficient for sanding.

HOW TO OPERATE THE MACHINE

Starting the machine

How to use the machine

The sander is usually held with both hands and placed

between the legs with your body leaning backward. You can

also use it on your knees.

The high speed of the disc will sand the surface without any

additional pressure. Do not press on the edger while

sanding.

Pressing on the machine could leave marks on the floor,

burn the wood, overheat the motor and wear the brushes

faster; shortening the life of the machine.