9

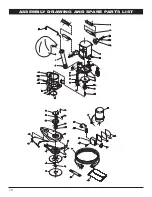

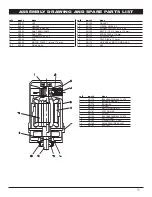

Fig.23

Fig.24

Fig.25

MAINTENANCE

EQUIPMENT

Wheel replacement

For proper machine operation, inspect the wheels for

wearing and to ensure the working angle is not altered

as the wheels wear down.

The proper working angle is necessary to maintain:

- Adequate dust suction

- proper sanding finish

Replace wheels as required to maintain the proper

working angle.

Dust suction

The machine is equipped with a dustbag. For

optimum performanc:

1

The working angle should be the adequate. A tilted

machine is not able to vacuum properly.

2

Empty the dustbag when it is 1/3 full. Suction

becomes less effective when the bag gets too full.

3

Do not use the machine with more than one disk of

sandpaper.

4

The bag is made with a special material which lets

air through, but not dust.

5

Change the dustbag several times a year, even if it

is not torn; the aging of material due to dust

accumulation will obstruct the air circulation and

therefore cause faulty suction.

Tool bag

A tool bag with wrenches is provided for machine

maintenance.