Chapter 7 Alarm

ADSD-S-S

77

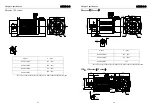

illegal code wiring is errors

wiring

shielding wire

encoder fault

Checking encoder

signal

changing the

encoder

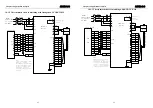

Err 33

province

line encoder

signal error

motor model is not

properly set

checking motor model

and confirming

standard motor

province line in the

encoder

resetting

motor model

Chapter 8 Maintenance and Inspection

ADSD-S-S

78

Chapter 8 Maintenance and inspection

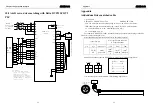

8-1 Basic inspection

Item

Content of inspection

Periodically inspect the screws of the servo drive, motor shaft, terminal block

and the connection to mechanical system. Tighten screws as necessary as they

may loosen due to vibration and varying temperatures.

Ensure that oil, water, metallic particles or any foreign objects do not fall inside

the servo drive, motor, control panel or ventilation slots and holes. As these will

cause damage.

Ensure the correct installation and the control panel. It should be free from

airborne dust, harmful gases or liquids.

General

Inspection

Ensure that all wiring instructions and recommendations are followed;

otherwise damage to the drive and or motor may result.

To avoid an electric shock, be sure to connect the ground terminal of servo

drive to the ground terminal of control panel.

Before making any connection, wait 10 minutes for capacitors to discharge after

the power is disconnected, alternatively, use an appropriate discharge device to

discharge.

Ensure that all wiring terminals are correctly insulated.

Ensure that all wiring is correct or damage and or malfunction may result.

Visually check to ensure that there are not any unused screws, metal strips, or

any conductive or inflammable materials inside the drive.

Make sure control switch is OFF.

Servo controller and exterior brake resistant can’t be installed on combustible

object.

To avoid electromagnetic breaker invalid, please check the circuit of

immediately stop and cutting off power.

Inspection

before

operation

(

Control

power is not

applied

)

When electronic equipments are being interfered around servo drive, Please use

other equipment to reduce this interference.

Ensure that detector cable is not over tension. When servo motor is working,

Please take caution to avoid attrition between cable and machine member.

If the servo motor has phenomenon of vibration and big noise, please contact to

manufacturer.

Confirming all parameters are proper set, difference of mechanical features will

lead to unpredictable motion. Do not excessive adjust parameters.

Inspection

before

working

(

Control

power is

applied

)

Resetting parameter should be done under drive status of (SERVO OFF).